Share

Pin

Tweet

Send

Share

Send

A very convenient, manual belt sander from a grinder can be made with your own hands. With the help of such a tool, it is good to sharpen an ax, knives, etc. To process a surface at any angle, giving it an even plane. In general, those who work with iron or wood will appreciate this mini machine.

Sharpen the cutting edge of the ax:

With such sharpening, the angle will not float away.

How to make a belt grinder from a grinder

The mount to grip the grinder will be made of a piece of thick steel, about 10 mm thick. Drill a hole for the neck of the angle grinder.

We saw a wide cut.

Grinder trim mount.

Then we clean and grind everything to have a beautiful and safe look.

We drill a hole with the legs of the clamping device.

Then we cut the thread on the wide side.

As a result, this mount can easily be put on the Bulgarians and clamped so that everything keeps tight.

Try on.

Now you need to make a roller that will rotate the tape from sandpaper. We take a chipboard and with the help of nozzles of large diameters we cut kruglyashi. To get a wide roller round glue them together.

Then we will drill a hole with a pen drill at once in all.

Then we clamp in a vice and with a triangular file we make an internal hole for the hexagon.

Like this.

We take a wide nut and make notches on the planes with a file.

They are needed to keep the nut in the tree better.

We part two-component glue on an epoxy basis and we paste a nut with notches in a wooden roller.

After the glue dries, we clamp the roller into the lathe.

Stitch under an ellipse. This is necessary so that the tape does not fly off. Then grind with sandpaper until smooth.

It came to the second video. It is made of three bearings pressed in ow.

Let's make two of these ears.

Dress on the edges of the protruding shaft.

Weld the plate. The result is a U-shaped part holding the roller.

To prevent the shaft from flying out, fix by welding

Now let's make the frame. It will take two steel pipes of different diameters so that one enters the other.

A flat plate is welded onto a pipe of larger diameter. It is needed so that during grinding press on the tape.

We weld a roller from bearings to a thin pipe.

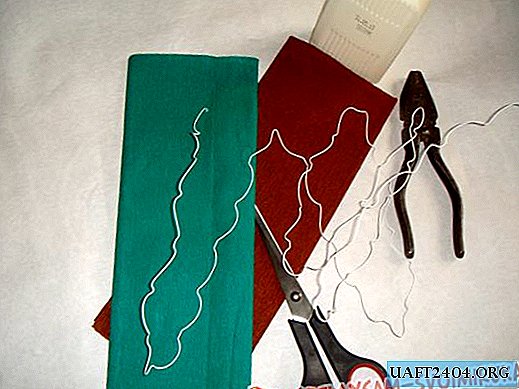

We take a ring of sandpaper (sold in construction stores), insert the pipe into the pipe and estimate the approximate size of the entire device.

We saw off the long ends of the pipes. We make a wide groove in a thin pipe, and a hole in a thick pipe.

We weld a nut to the hole.

To the ring mount - a segment from the pipe.

We weld the bar with the mount.

Paint with spray paint.

After drying, insert the pipe into the pipe. We fix it with a bolt.

We dress on the grinder and also fix it with a bolt.

It remains to put on a strip of sandpaper and the manual belt sander is ready.

It works great.

If there are vibrations of the tape, then tighten it. But a strong interference is not necessary. In general, at high speeds, the tape behaves stably.

See the video for more instructions.

Share

Pin

Tweet

Send

Share

Send