Share

Pin

Tweet

Send

Share

Send

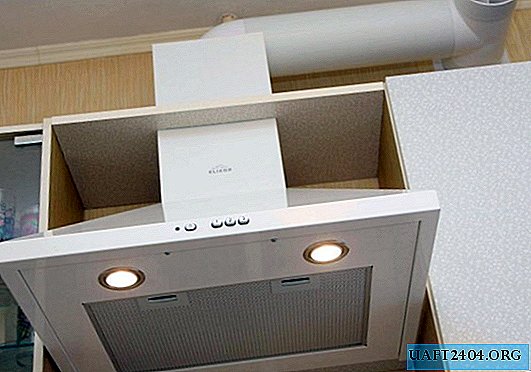

With a standard installation of a kitchen hood, the natural ventilation channel is blocked, so the air exhaust only works for the period the fan is turned on. I propose a mounting method in which it is possible to fully combine the two systems without losing their effectiveness.

Materials used

From the materials I needed:

- ventilation pipe with a diameter of 125 mm;

- knee 90 degrees;

- tee;

- check flap valve;

- ventilation grill flange;

- adapter with a diameter of 160 mm to 125 mm;

- silicone sealant;

- self-adhesive sheet heat and sound insulator 5 mm;

- gypsum plaster.

Combination of forced kitchen and natural cooker hoods

Before assembling the duct, you must first prepare the exhaust duct in the wall. To do this, it needs to be cleaned and made as smooth as possible. This is a rather painstaking and dusty job. If the ventilation was poorly cleaned, then several dust buckets can be collected from the mine, as I had. The cleaned channel turned out to be rough, which does not contribute to the normal movement of air. In the aisles of reach I had to plaster it with gypsum. In addition, I plastered the right angle at the bottom of the ventilation window, making a rounded, smooth rise so that the air escapes with less resistance, without abutting against the wall, which reduces its speed.

After partial drying of the plaster, a piece of pipe 10 cm long was walled into the wall, having a neck protruding by 5 cm. It is placed not horizontally, but with a slight slope to the floor. The ventilation duct will then be connected to it.

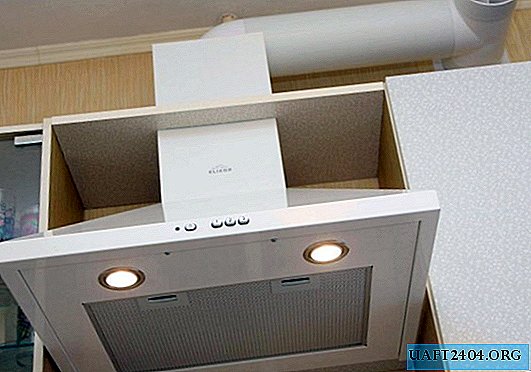

My hood has an outlet diameter of 160 mm, so I fit an adapter of 125 mm on it. I already attach a pipe segment to it. I select its length in such a way that after installation at the top of the knee 90 degrees, the height of the entire structure reaches the level of the pipe at the entrance to the ventilation duct in the wall.

Next, I take a tee and install it on a pipe coming from the wall. It is necessary to set so that its central entrance is directed to the elbow of the hood.

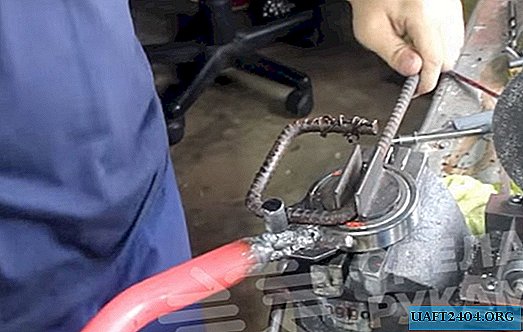

I cut a piece of pipe for installation from the knee to the tee. After its installation, the hood is already fully connected to the shaft. It remains to deal with the check valve. For this design, you need a valve with one damper and with an offset axis. Since the valve diffuser is very long, I cut away half of it so that the section of the natural ventilation channel is shorter and looks neat.

After preparing all the parts, you need to carry out the final assembly. I disassemble the entire structure and begin to assemble it with a coating of compounds with silicone. After solidification, it will be soft, so it will dampen part of the vibration. Before gluing the tee, I put the flange of the ventilation grill on the pipe outlet from the wall. It acts as a decorative panel covering the plaster. I also glue it so as not to use screws. I collect everything on the sealant except the check valve.

I have a powerful hood, so at the place where her channel goes into a narrower pipe by 125 mm, a hum is produced. To remove the noise, I pasted an adapter and a vertical pipe with soundproofing material, as long as it is hidden by a decorative box.

Now the most responsible and painstaking thing remains - to set the check valve. It is installed in the free exit of the tee. For sealing I use electrical tape. I make a coil on the diffuser, and then install the valve. I put it in such a way that the axis of the petal is not horizontal, but almost vertical, but with a slight shift of the upper point towards the forced exhaust.

The valve diffuser is inclined relative to the floor, since the channel pipe itself exits the wall with a known offset. In addition, there is a slight bias along the axis of its door. Thanks to this, the valve is always open. Even if you cover it, then under the influence of gravity the petal will open.

Having achieved the opening of the valve under gravity, we can assume that the system is complete. Now, if you turn on the forced exhaust, then the flow pumped in it presses on the valve petal and it closes tightly.

The air supplied by the fan will only go into the shaft, and the valve itself will not penetrate. As soon as the hood is turned off, the petal itself will return to its place, and then natural ventilation will work.

This option of connecting forced extraction will allow to maintain the effectiveness of natural air exchange. If you put the corrugation and tightly close the shaft window, then in this case, when the engine is off, the air movement will be almost completely stopped. My mounting option does not require the use of any mounts. Due to the bonding of the silicone elements, the design has sufficient rigidity to reliably hold between the fixed hood and the embedded neck on the shaft window.

Share

Pin

Tweet

Send

Share

Send