Share

Pin

Tweet

Send

Share

Send

Hardened alloy steels are particularly difficult to handle. In order to have more specifics in our actions, we will dwell on S30V stainless steel, from which excellent blades for knives are made.

Of course, drilling a hole in steel with such characteristics is much more difficult than in ordinary steels, but in principle it is possible. Below we will consider a method of not so much drilling as burning.

What we need for this:

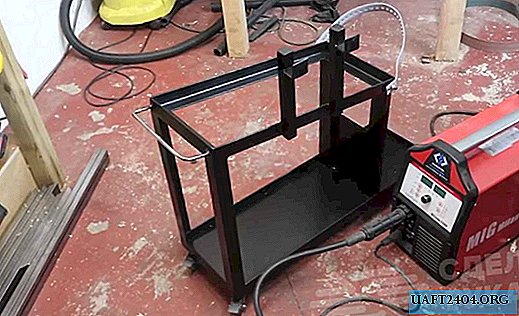

- powerful drilling machine;

- grinder with endless abrasive tape;

- metalwork vice;

- diamond drill;

- tungsten electrode.

As the test material, as already determined, we take a strip of hardened steel grade S30V with a size of 5 × 30 × 200 mm.

Steps for drilling-burning holes in hardened steel

To do this, we clamp the selected strip of steel in a metal vise, having previously outlined the places for the upcoming drilling. And so that the planned process proceeds without complications, we make indentations in places of future holes by means of a small diamond drill in diameter.

We perform further actions on a drilling machine using a pre-prepared home-made tool. It can be made of a tungsten electrode with a diameter of 2-4 mm. You can buy it in stores where welding transformers and accessories for this common type of work are sold.

Cut a piece of 30-40 mm long from the electrode, for example, using a grinder. We grind one end on a suitable abrasive tool so that it enters the recesses that we made on the test piece.

We insert our homemade tool into the drill chuck, which is able to provide a fairly significant vertical force on the spindle with our drill clamped in it.

As a result, a large friction force will be provided between the test plate and the rotating tool with the release of a huge amount of thermal energy.

As a result, both the drill and the section of the plate around the future hole will become red hot. To intensify the process, the spindle speed must be maximum.

If then a plate with drilled holes on both sides is processed on a grinder, then they will look quite presentable.

In this form, they can be used for planned purposes. If necessary, the holes can be expanded using a conventional drill, since after burning, the metal around them is released.

Share

Pin

Tweet

Send

Share

Send