Share

Pin

Tweet

Send

Share

Send

Will need

- turning and milling machine;

- Bulgarian;

- file for metal;

- passage and cutting tools;

- twist drills;

- disk mill;

- spanners;

- quenching equipment;

- calipers;

- cutting fluid.

Also, to make the Watts drill, you need a high-speed steel rod, and for the template - a steel circle.

Watts Drill Making

On the workpiece using a milling machine NGF-110 we perform three longitudinal grooves. The process will go with exertion, since the characteristics of the material of the carbide cutter are not much higher than that of a quick cutter.

Next, we clamp the workpiece with grooves in a vice and perform a profile of three cutting teeth with a grinder, starting from the slots. We sharpen the end face of the drill, and the side faces are not sharpened.

On special equipment for the manufacture of square holes, the Watts drill not only rotates around its longitudinal axis, but the axis itself makes a trajectory described by four ellipsoid arcs. But we will choose a different path.

Template making

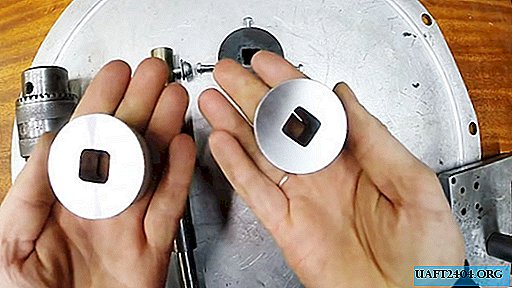

The second part is the template in which the Watts drill will rotate. In our case, the diameter of the drill is 15 mm. This means that the square made by him will be 15 × 15 mm.

To make sure that the Watts drill does not jam in the present template, place it in a strip of plastic with a square of 15 × 15 mm and start rotating the drill. It should not bite and cut chips from the sides of the square.

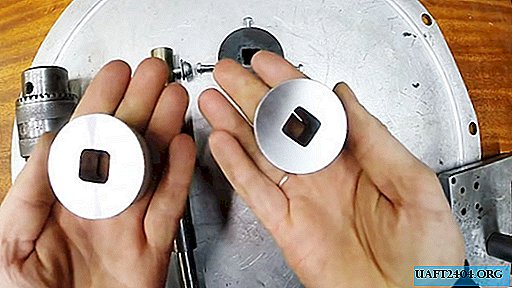

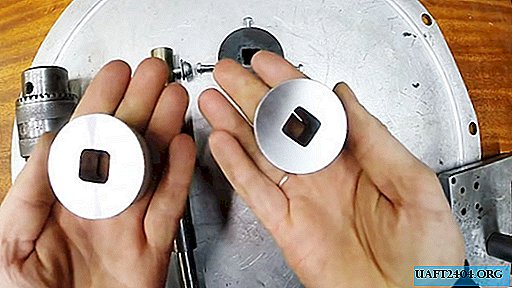

We clamp the copier blank into the lathe chuck and grind the end face. Then drill a 15 mm drill in the center of the through hole and drill it with a large diameter drill to the desired depth.

Through the cutter we bring the inner diameter of the large hole and grind the workpiece from the outside. Closer to the front end of the template, we drill 4 holes evenly in a circle, cut the threads under the bolts to fix the copier on the workpiece in which a square hole will be made.

We draw four lines on the back side of the template blank using a scriber and dividing head, which, intersecting, form a 15 × 15 mm square described around a hole with a diameter of 15 mm.

In the inner corners of the marked square, we drill 4 holes with a thin drill. We clamp the copier bowl into a vice and file with a file to form a square hole from a round hole. The Watts pattern and drill are designed to work together.

For hardening, we heat the template in a muffle furnace and lower it into a container with engine oil.

For less distortion of the Watts drill during operation, we produce an extension cord for it. This will make the square hole coaxial in length. We fix the drill in the extension cord with two bolts.

Square hole process

We fix the drill with an extension in the head of the lathe. To test the tool, we will make a square hole in the aluminum material.

We grind the end face and the side surface of the workpiece.

We install a template on the workpiece and make a small round hole in the place of the future square with a drill.

To soften the collisions of the Watts drill with the square of the template, grease this place with SHRUS grease.

We start the drill in the square of the copier and rotate the workpiece by the chuck by hand. If jamming or biting is not felt, turn on the machine.

We feed the tool forward and see the complex movements made by the drill in the area of the template. After some time, the output of the chips begins, which indicates that the process has begun.

Having reached the desired depth, turn off the machine, remove the headstock with the tool, remove the template and separate the cylinder with a length of about 30 mm from the workpiece with a cutter.

We make sure that the square hole is made in length without violating the alignment and lateral size. Our devices successfully passed the first test.

We proceed to a more complex process - the manufacture of a square hole in a steel billet. We also grind it along the end and the side surface. We wind and fix the template. We bring the tool and start drilling.

The process is being signaled by vibration of the drill and the appearance of chips. We feed the tool to the same 30 mm. Then we remove the template and cut off the workpiece with the resulting square hole.

Results

After grinding the ends of the blanks with square holes, we make sure that they turned out to be qualitative in the longitudinal and transverse directions, regardless of the material - aluminum or steel.

The drill bit and the square of the template also remained intact and did not even become dull, that is, they are again ready for work.

It is clear that for each size of the square hole you need a separate Watts drill, and the template, if approached creatively, can be made universal within certain limits.

Share

Pin

Tweet

Send

Share

Send