For reliable fixation of round pipes in a home workshop or in a garage, you can use home-made vertical mini-vice.

You can make them from scraps of metal - there is plenty of this "good" in any workshop. For homemade work, you will need two pieces of steel pipe (round) and pieces of metal plates.

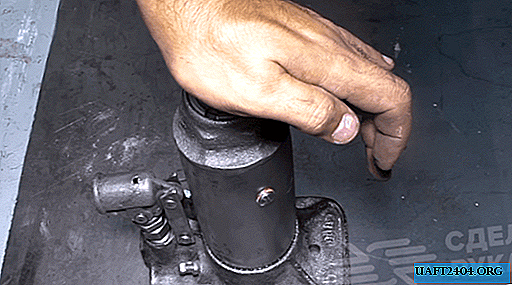

In general, the design is quite simple. The base of the vise is a metal plate. Two pieces of a round pipe (guides) are vertically attached to it.

In the lower part of the base there will be two clamping fixed jaws. You can make them from a strip of metal. Then they will still need to make slots in them.

The main stages of work

To fix the pipes, two holes need to be drilled into the base. You also need to cut off the steel plate, which is installed on top of the pipe sections and presses them. As fasteners, long bolts and nuts are used.

It will also be necessary to drill holes in the fixed jaws, they are connected using two bolts.

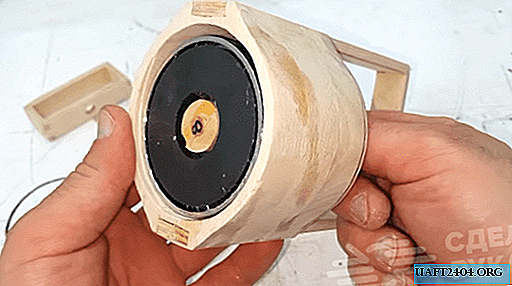

At the next stage, it is necessary to cut another part from a strip of metal, and make semicircular cuts along the edges so that the plate can move between the guides. Then, in the center of this workpiece, you need to drill a hole for the screw.

Next, a clamping sponge is welded to the movable plate. In the upper plate, which is located on top of the pipes, you need to drill a hole for the stud. At the end of the hairpin, the author makes a knob.

After that, all the parts must be cleaned with a grinder, and you can already start assembling. For details on how to make a vertical mini vise for fixing round pipes, see this video.