Many forge products can be made "cold", without the use of metal heating or special machines. And for this you only need a fork - a simple home-made fixture that is easy to make on your own.

Working with cold forks is easy. Much easier than hammering on the anvil. With the help of this device you can make beautiful curls from a round log and a steel strip for decorative design of fence sections, benches, window bars, etc.

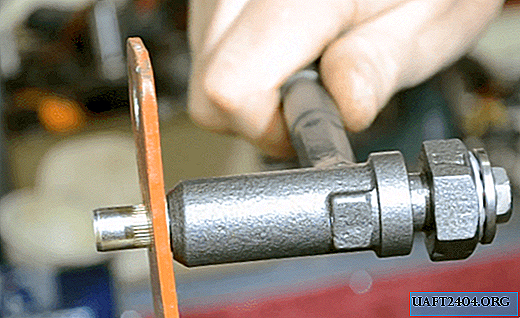

You can make forks for cold forging from improvised materials. For example, for a fork, to bend round logs and square rods, the rod from the front shock absorber from the Zhiguli is suitable. For a fork, to bend pieces of steel strip, you can use the rod from the rear shock absorber "Niva".

Features of using forks for forging

Working with cold forks is easy and convenient. The simplest fork can be made from pieces of reinforcement with a diameter of 16 mm for an hour. However, for greater convenience, it is better to make a worktable for workpieces. For this you can use a plate with a thickness of 4-5 mm.

A piece of a construction corner of 40x40 mm is welded from the bottom of the plate. With the help of a corner, the fork with the platform is fixed in a bench vise. The lever fork is best made from a piece of spring that is inserted into the steel tube.

Details on how to work with cold forging forks and curls of various shapes can be found in the video on our website.