If the bearings on the shafts can still be removed somehow with improvised means, then the bearings that are pressed into the blind mounting "nests" without a special tool will be difficult to remove. In this case, you will need a bearing puller, which can be made from available materials with your own hands.

To make this device you will need a round metal blank of the desired diameter (determined individually). You can also use a thick-walled pipe, but it is much more difficult to get it than a blank. We drill a hole in the workpiece, and then process it on a lathe.

Using a grinder with a cutting wheel or, for example, on a band saw, we cut the part into two parts (that is, cut it in half). Then you need an anchor bolt, which is inserted into the "hollow" between the two halves of the round billet.

The main stages of work

Cut a small piece of a rectangular metal plate about 12-14 mm thick. Then we mark and drill a through hole in the middle of the workpiece. Also cut two pieces of steel strip of the same length. We weld all the blanks together in a U-shaped part.

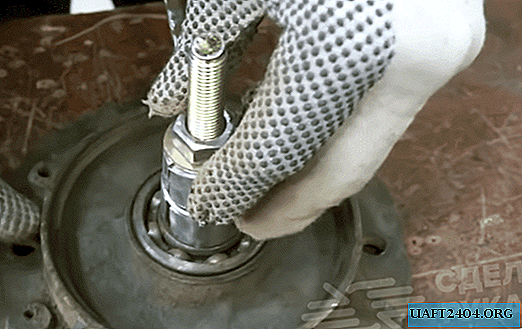

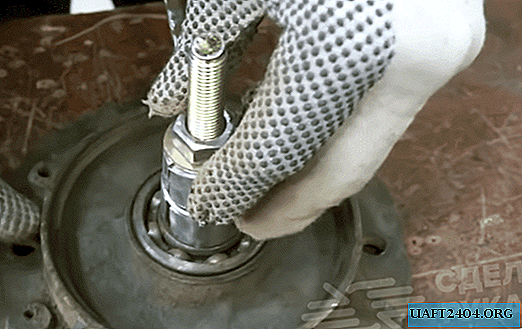

Both halves of a round blank together with an anchor bolt are connected by a half ring from a steel spring. Then cut off a piece of smooth reinforcement and weld it to the nut. At the last stage of work, we assemble a homemade device.

For more information on how to make a very simple and convenient puller for removing bearings, see the video on the website.