Making an aluminum handle for an old ax is more a pleasure process. Such homemade goods will not be of any use to the house, since the ax will be twice as heavy as an ordinary wooden handle.

The main goal of this work: 1) to restore the old ax and give it a second life; 2) make an original ax with your own hands, which will not be used for chopping firewood or others, but will simply stand in a prominent place as a beautiful exhibit.

First of all, it is necessary to clean the surface of the ax from rust. One of the effective methods is an electrochemical reaction (electrolysis) in a solution of sodium carbonate and water. The ax itself is connected to the "minus" of the car battery, and the steel rods to the "plus".

Making aluminum pen

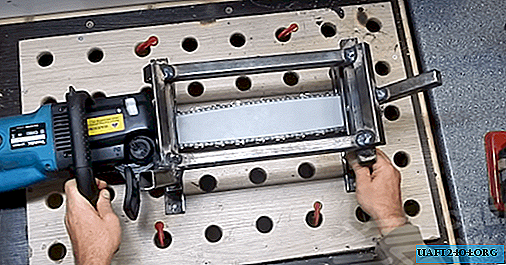

On a foam blank we draw a sketch of the future aluminum hatchet, and then cut it out using a special machine for hot cutting of polyurethane foam (or you can use other available methods). Grind the finished sample with sandpaper.

At the next stage, glue the foam blanks to the ax with hot melt adhesive. Then glue the sprues. We coat the resulting form with gypsum plaster for high-quality casting. The layer of plaster should be thin.

Next, put the "horny" form with an ax in a wooden box with sand, put steel caps on the sprues, and fill them with sand. Then we melt with aluminum and fill in the ax. As a result, it turned out, albeit a massive, but original handle for the old ax.

The detailed process of manufacturing a template from foam and pour aluminum can be viewed in the video on the website.