The factory T-key for clamping the three-jaw power drill chuck, which comes complete with the tool, is not particularly convenient to use. With a constant change of drills, that part happens when performing a large volume of drilling work, fingers begin to hurt. Naturally, this causes a certain discomfort.

In addition, the standard key has a small lever, and fixing the drill very often turns out to be unreliable. Therefore, if you encounter this problem, you can modify the key a little to make it more convenient to use.

The main stages of refinement

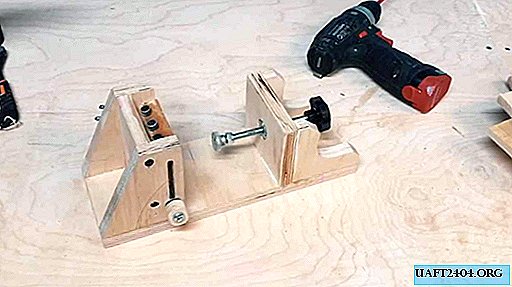

First of all, you need to cut off the head of the factory key for the electric drill chuck, but not under the root, but with the shank. We clamp the key in a vice and, using a grinder or a hand hacksaw, cut off the necessary part.

Then we put on the shank a replaceable head from the spanner by 10 mm and drill a through hole at an angle of 90 degrees on a drilling machine. Then we make a small depression using a countersink and insert a cotter pin into the hole.

The cotter pin head needs to be drowned a little in the recess, and the ends are bred in different directions and pressed against the surface of the nozzle. Since the "tendrils" of the cotter pin are long, they need to be shortened a little, cutting off the grinder.

Summarize the work

Now it will be much more convenient to twist and unscrew the drill cam chuck - you can use a screwdriver or ratchet for this. See the video on the site for the step-by-step process of finalizing the standard key.