Using this home-made electric file from angle grinders (grinder) it is very convenient to clean the welds, as well as to grind metal and wooden workpieces or parts located in hard-to-reach places.

Despite the fact that this device is intended mainly for manual work only, the electric file can also be used stationary by fixing the grinder to the table using clamps or in another way.

The main stages of work

In two sections of a strip of metal with a thickness of 2-3 mm and a width of 40 mm, you need to drill holes, after which we give one of the blanks the desired shape on a bending press. We clean the two strips with a grinder, and then weld them together, clamped in a vice. Moreover, the entire seam can not be scalded - just put a few tacks along the entire length.

On the back of the L-shaped bend on the strip, you need to weld a segment of the stud or a metal rod, on which a sleeve from an aluminum tube is worn - it is welded to a piece of steel corner. The strips themselves are inserted into the guide. The result is a tensioning mechanism for the sanding belt, adjustable in length.

An integral part is cut from a sheet of metal, which is attached to the gear case - in it you first need to drill a hole with a diameter, like a regular protective casing of an angle grinder. We cut the spikes inside, after which we finish them with a file.

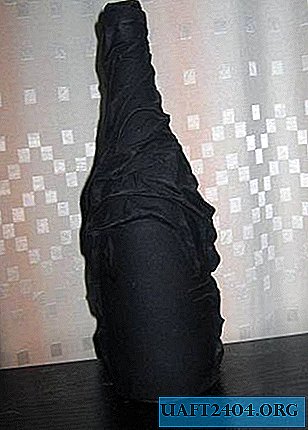

Assembly of the electric file

At the last stage, we collect all the structural elements together (first they need to be cleaned and painted), we pull the sanding belt and the electric file from the grinder is ready to work. For a detailed process of manufacturing and assembling a grinder, see the video on the site.