Conventional manual nut crackers, which are used for chopping walnuts, do not do their job well enough and break quickly, as the central axis of the fastening of the two halves of the structure is loosened. However, a manual nut cracker can be used to make a mechanical one, using a clamp and a handle from a cast-iron meat grinder.

A home-made version of the nut cracker is more convenient and practical to use, and walnuts can be chopped with it much faster than manually. It is best to use the details of a meat grinder made in the USSR for this homemade product, since Soviet-hardened cast iron lends itself well to welding even with ordinary electrodes.

The process of making a nut cracker

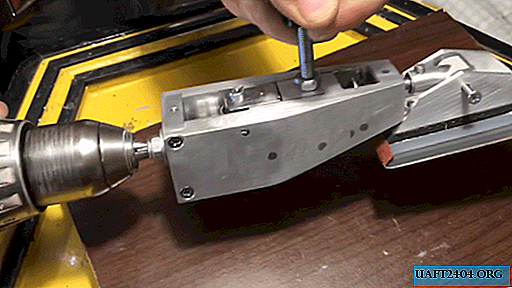

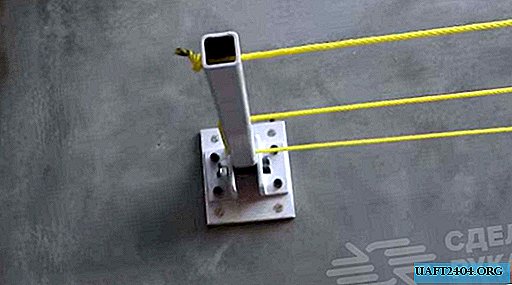

We weld a piece of a square-shaped profile pipe to the clamp from the meat grinder, and to it is a bearing housing. The shaft of a mechanical nut cracker is made without welding, the parts are connected to each other by screws. Therefore, this node is easy to disassemble if necessary. The shaft is inserted into the bearing (outer diameter - 40 mm, inner - 17 mm).

Please note that it is better to take the bearing from disassembly, since there is no point in putting new bearings. The end of the shaft is turned in the shape of a rectangle so that it fits inside the handle of the manual nut cracker. As screws, two M4 screws are used. A holder for a bearing with an external diameter of 19 mm is fixed on the second handle.

The area on which the bearing will be rolled back is made of a piece of sheet steel and a steel pipe cut with a diameter of 100 mm, the parts are welded together. It is attached to the body with two M5 screws. See all the steps of assembling a mechanical nut cracker from a conventional meat grinder in the video on the website.