When tightening the nuts and bolts (especially during the repair of the hinges of the suspension, the intake manifold and other components of the car), it is necessary to observe the strictly specified tightening torque. Detailed information on acceptable values can be found on the Internet without any problems.

By observing the exact tightening torque of nuts and bolts, the mating surfaces are more firmly and evenly abut against each other. It is for tightening with a certain effort that a torque wrench is used, which can be mechanical and semi-automatic.

Such an instrument is not cheap, so buying it to use it a couple of times does not make sense. Of course, if there is extra money, then you can buy a torque wrench. However, if your main goal is to save money and do away with improvised means, then in this case it is more reasonable to make an almost torque wrench with your own hands.

The principle of the tool

Semi-automatic torque wrenches resemble in shape and design a conventional ratchet wrench, which is used for socket heads. The only significant difference from their "counterparts" is the presence of a special ratchet mechanism, which allows the built-in gear to rotate in two directions.

For example, to bring the tool handle back after a full revolution, you need to apply a relatively small force. But to tighten the nut a little more effort should be applied.

When the desired value is reached, the ratchet gear simply starts to slip (a characteristic sound is heard), as a result of which the nut or bolt is no longer tightened. This eliminates the likelihood that the thread will break.

Torque wrenches with a scale for measuring the applied force by default do not have the ability to limit torque when a specified value is reached. In this case, this moment must be controlled independently using a mechanical or electronic digital measuring scale.

A homemade almost torque wrench, depending on the design, can work according to the example of the first and second options described above.

Why count Newtons and meters

Before proceeding with the manufacture of a simple home-made torque wrench for tightening bolts and nuts, it will be necessary to carry out some calculations. For example, in order to achieve a tightening torque of 10 N * m, it is necessary to apply a force equal to one kilogram of force to a lever or shoulder 1 meter long.

But only in the conditions of a home workshop or garage, a meter lever is not the most practical and convenient option. Ideally, it is better to use a shoulder within 20-50 cm. And in order to correctly calculate what force must be applied to the lever to achieve the required tightening torque, Newtons and meters should be counted.

However, it is not necessary to go into the wilds of mathematical equations. The desired values can be calculated without problems in a proportional ratio. That is, if we take as a basis that to obtain a torque of 10 N * m, you need to apply a force of 1 kg per meter lever, then it is similarly easy to calculate what force will have to be applied to a lever of shorter length.

The shorter the lever used, the greater the effort required to tighten the bolt or nut - this is, so to speak, an axiom. For example, if instead of a meter, you use a lever 50 cm long, then to obtain a torque of 10 N * m you need to apply a force equal to 2 kg.

If you use a lever, for example, 22 cm long, then the force will already be 4.5 kg. In other words, you need to divide the torque (10 N * m) by the length of the lever (in this case - 0, 22 m) and multiply by 0.1. Using this simple formula, you can easily calculate what specific force is required to tighten the nut.

Buy or do?

In the process of carrying out repair work on car maintenance, almost every vehicle owner is faced with the fact that it is necessary to tighten a bolt or nut with a certain effort, but there is no torque wrench at hand. Do not run to the store to buy an expensive tool, use it for 20-30 minutes and forget it for a year.

Therefore, the best option is to make a homemade torque wrench for tightening nuts and bolts. Moreover, you can make a tool like a ratchet with a ratchet mechanism, as well as made by analogy with a simpler design - using conventional hand weights.

Homemade torque wrench without scale

This version of the homemade key does not have a scale, as in the factory dynamometer, but the tightening torque on it can still be adjusted. This simple hand tool is used to apply the same force to tighten nuts and bolts. Thanks to the system, which operates at a certain load, it becomes clear that the desired limit has been reached. On how to make a torque wrench with your own hands, read below.

This tool is very simple to manufacture, while it can be much more reliable than factory keys, and gives a great moment when tightening nuts or bolts, due to the length of the handle. To make a homemade torque wrench without a scale yourself, you will need very simple and affordable materials:

- a half-inch piece of steel pipe;

- two plates 5 mm thick with holes with a diameter of 12 mm;

- a long bolt with a nut of suitable diameter;

- one home-made thick-walled washer;

- spring and metal ball from the bearing.

We weld “ears” made of a metal plate 5 mm thick to a half-inch steel tube. Between the plates we place a thick-walled washer and fix it with a steel "finger".

Inside the tube we install a pusher with a ball from the bearing (in it you first need to make a small recess equal to ½ of the diameter of the ball). Following the pusher, we install a spring and press it with a bolt and nut, which is welded to the end of the half-inch tube. Another deepening under the ball must be done in the thickest washer.

At the last stage of work, the only thing left to do is weld the lever - for example, from a small section of the pipe. Please note that the longer the lever is, the less force will have to be applied when tightening the nuts or bolts. A key for the socket heads is welded to the lever.

The applied force is easily adjusted by means of a clamping bolt. The more you tighten the bolt, the greater the force will need to be applied when tightening. Here is such a practical home-made torque wrench without a scale you can do it yourself from improvised and inexpensive materials.

Hand weight tightening

Alternatively, as a replacement for a factory or homemade torque wrench in the form of a ratchet, you can take a regular wrench or combination wrench. We attach to it a hand-held scale such as "canter" or "steelyard" (or you can, for example, take it with a digital display), and tighten the bolt or nut. Also quite a working option for yourself at home, if there is nothing at hand at all.

To tighten the nuts or bolts with a certain force using a hand-held scale, most often a “steelyard” of 20-30 kg and a piece of steel pipe 50 cm long (but possibly less) with a suitable inner diameter of at least 25-30 mm will be enough could be put on a key. In the event that tightening of large moments is required, the appropriate scales must be selected.

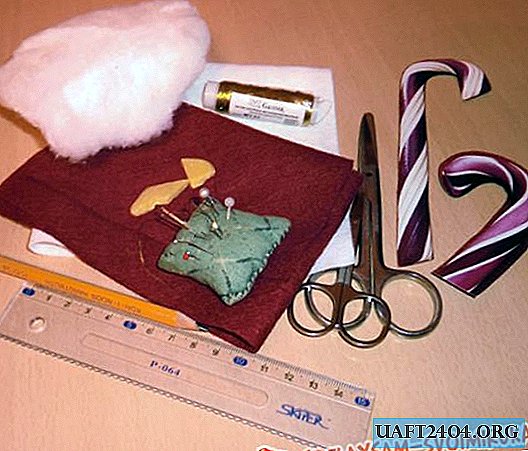

What is needed for work:

- a wrench (open-end or spanner) on which a piece of steel pipe about 40-50 cm long is put on;

- spring cantor (hand-held scales) with a "limit" of up to about 20-30 kg. You can also use electronic scales for the manufacture of a torque device.

Tightening process

First you need to install a ring spanner or open-end wrench on a bolt or nut, and at the other end we hook the hook of a hand-held scale. Having calculated the necessary effort in advance, we pull the ring of weights, while maintaining 90 degrees, until the desired value is reached.

Thus, even without a torque wrench at hand in the garage or workshop, you can tighten the nut and bolt connection with the necessary force and accurate torque.