Share

Pin

Tweet

Send

Share

Send

Buying such an expensive thing as an engraver is only half the battle (however, to do it yourself is also not a tricky business). During the entire time of use, it is also advisable to update and replenish the existing stocks of drills, mills and other nozzles, which are also not cheap. In any case, they (for some reason!) Are more expensive than consumables and nozzles for the same standard size tool. But it is not necessary to buy them all in a row - some nozzles can be quite easily made independently. Of course, it is unlikely that it will be possible to make such complex tools as a wood milling cutter, drill or diamond drill for glass engraving, but here, for example, small files for cutting wood and plastic, grinding and felt disks, you can easily do it yourself.

Even in the absence of skills. I think that with a pair of scissors, each person is able to cut the correct circle drawn by a compass on the workpiece. In addition, you will not find some consumables in ordinary stores selling such goods. We have to order and wait a long time when they come, and whether they will come at all ... And if they do, then it is not a fact that they will turn out to be of high quality and reliable. The grinding discs I recently received by mail were so fragile that one of them broke due to a little pressure ... In general, if you want to do something well, do it yourself! Today we will consider several options for the independent manufacture of a more durable tool.

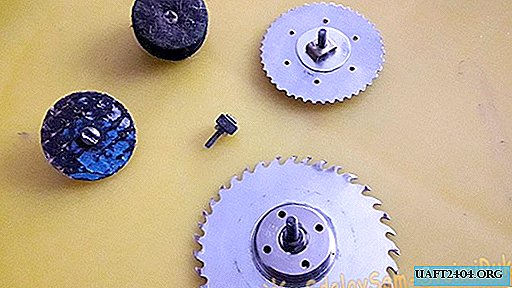

Saw blades for wood and plastic

You will need:

- A metal circle, or piece of sheet metal, with a thickness of not more than a millimeter.

- Compass and pencil.

- Scissors.

- Drill and drill.

- Emery machine with cutting blade.

- Metal bolt with nut from the children's designer, or from a prefabricated electric plug.

First you need to draw a circle on a sheet of metal with a diameter of 3-5 cm. Using a compass and a pencil. I had finished metal circles from the chandelier, only with a large hole in the center. In order to fit the hole under a small bolt, cut out (or take ready, if any) two washers so that they cover the hole on the future saw blade. We make a hole for the bolt in the center of each washer, squeeze the disk hole on both sides with washers, align it in the center, and tighten it with the nut and bolt.

Next, you need to cut the teeth of the disc.

We make oblique cuts along the entire edge of the disk, with a depth of 3-4 mm, and in increments of 2 mm. You can use it.

A blade for cutting plastic, we do exactly the same, repeating the above procedures, except for sharpening the teeth. Here, the cuts should be done at a right angle, two mm deep, and in two mm increments as well.

The teeth should be short and wide. This disk can be used to saw plastics of different densities, as well as plexiglass and textolites.

Grinding and felt wheels

You will need:

- Thin grinding disc (you can use it, or a chip in general, but not thicker than a millimeter).

- A piece of felt, 7-10 mm thick (just right from the felt boot).

- Compass and pencil

- Knife.

- Scissors for metal.

- Emery machine.

- Thin bolt with nut.

Here, too, the manufacture is not very different from the first two options. We also draw a 3-5 cm circle with a compass.

Only the felt is probably best cut with a sharp knife, as it is quite thick, and I crushed all my fingers with scissors. A grinding wheel is best cut or scissors for metal, or on an emery machine with the same cutting wheel. Next, we make holes in the centers of the circles, and tighten on both sides with bolts and nuts.

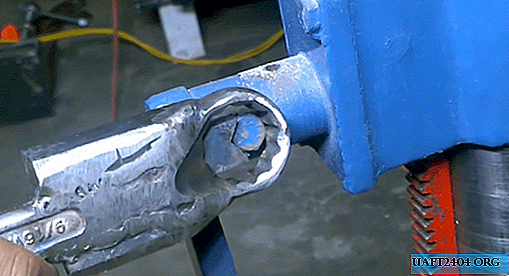

Miniature Engraving Cutter

You will need:

- Wheel from the lighter, which carves a spark of flint.

- The bolt that will fit into the hole of the wheel, and the nut to this bolt.

In this design, almost nothing needs to be done. Just thread the bolt into the wheel and tighten it with the nut on the other side. The simplest cutter is ready. She can make inscriptions and drawings on wood, plastic, and even on aluminum and brass.

In general, there are many options, you just need to connect imagination, and a little patience.

Share

Pin

Tweet

Send

Share

Send