Share

Pin

Tweet

Send

Share

Send

With the wing nuts, everything is clear and understandable: they are needed where it is often necessary to unscrew and tighten them, and quite tightly, without using keys. This can be electrical terminals, container covers, inspection hatches, etc.

But sometimes there is a need to use not a wing nut, but a wing bolt. For example, in the operation of a quick coupler consisting of massive parts. On sale, wing bolts, unlike wing nuts, are not common. Fortunately, you can do it yourself.

Would need

To make a wing bolt, you will need a regular hex bolt and any plastic bottle.

Of the tools and fixtures, it is enough to have:

- vise;

- hacksaw for metal;

- building hair dryer;

- pliers or pliers;

- mini drill.

The sequence of manufacturing the wing bolt

Realize the following step-by-step instructions for almost any adult.

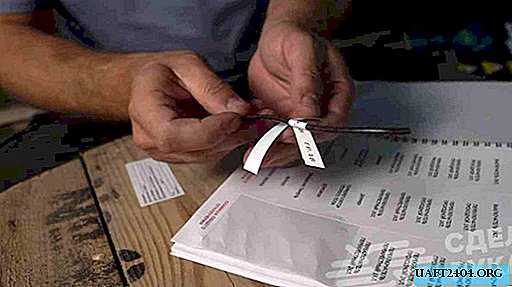

1. Using a hacksaw, we cut off a part of the neck with a thread from the plastic bottle, which should be slightly higher in height than the height of the bolt head.

2. We fix the bolt in a vise for the rod, so that its head rises slightly above the upper faces of the vise clamping jaws.

3. From above we put on the cut-off part of the neck of the bottle with a thread on the head of the bolt.

4. Using a hair dryer, we heat from a certain distance the cut fragment of the PET bottle until it softens. Depending on the temperature of the air stream, 5-10 seconds or so is enough.

5. We take two pliers and squeeze an annular plastic fragment from two opposite sides, so that it tightly grabs the head of the bolt and at the same time extends in opposite directions and, at the same time, its strips must be welded (glued) together.

6. If during the formation of bends the temperature of the plastic decreased and it lost fluidity, then you can again warm them carefully with warm air and bring the work to the end.

7. Using a mini drill, knife and scissors, while the plastic is warm, we remove the sag, trim the ends and cut off the lower part of the wing of the lamb so that they do not interfere with tightening the bolt to the end.

As a result, we get a wing bolt with a plastic wing quite securely sitting on its head. The strength of the resulting combined part is such that breaking it by hand will not be easy.

In addition to the manufacture of a wing bolt or nut, this method can be used to unscrew nuts and bolts in unforeseen situations when, for example, a suitable key was not at hand.

Holds very securely and just does not unscrew or break with your hands.

Share

Pin

Tweet

Send

Share

Send