Share

Pin

Tweet

Send

Share

Send

In order not to spend money, you can try to make a fixture with the given functions yourself, for which you need to have at least basic locksmith skills, as well as stock up on some tools and materials.

Will need

In the upcoming work, the following tools and devices will help us:

- drilling machine or electric drill;

- drills of the required diameter;

- electromechanical emery wheel;

- bench vise;

- hacksaw for metal or grinder;

- a set of spacers (pieces of thick-walled pipes of various lengths);

- extension for vise collar (piece of suitable pipe).

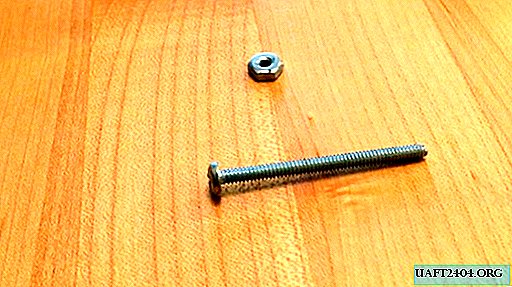

To make the required tool, a kind of broach, we use the working part of the Allen key (Allen key, Imbus key) with a working section of a suitable cross section. It is designed to tighten and loosen screws having a cylindrical head and a hexagonal recess.

The process of creating a tool for the hex hole

This stage is the most responsible and important, since the quality of the proposed hexagonal hole in the metal will depend on the reliability and dimensional accuracy of the planned broach.

The work sequence should be approximately as follows:

1. Usually hex keys are L-shaped. Cut off the short part (handle) below the bend with a hacksaw for metal or grinder.

2. We form from a flat (working) part a workpiece with a length of 50 to 75 mm, depending on the transverse size of the future tool.

3. Using suitable means (an emery wheel, a very hard file) we give the workpiece the shape of a light uniform cone, preserving the same cut in any section along the perimeter.

4. Using the edges of the emery wheel, we form from three to five transverse rings.

They are needed to improve the cutting properties of the device and the accumulation (retention) of metal removed during processing.

Hexagonal hole forming process

We perform this work in the following sequence:

1. First, it is necessary to drill with a drill or a drilling machine in metal, an auxiliary hole with a diameter that can be calculated from a very simple relationship obtained experimentally:

DSP = Dshstgr. × 1,020, where D - diameter of the auxiliary hole, Dшггр. - thickness (size) of the hexagon.

For example, if it is 15 mm thick (the distance between the opposite faces), the diameter of the preliminary hole should be: 15 mm × 1,020 = 15,30 mm.

2. Insert the guide part of the homemade tool into the drilled hole in the metal part and, for reliability, lightly hit the opposite end with a hammer.

3. The resulting structure (a metal plate with a tool fixed in it that forms a hexagonal hole) is placed between the jaws of the vice and set the spacer suitable for the length of the spacer for receiving a home-made tool on the outlet side of the broach.

4. We move the jaws of the vice, rotating the collar. In case of high resistance, we put on an extension cord to increase the shoulder and, accordingly, the clamping force. We continue this process until the broach completely passes through the metal plate.

5. Unclench the jaws of the vice and knock out a broach with a hammer from the formed hole in the opposite direction. To improve the quality of the hole, we drive the broach on the other hand in the same order as in paragraph 4.

6. The final operation involves the removal of residual metal particles and the resulting burrs. To do this, you can use the grinder, file and sandpaper.

The metal in which we are going to make a hexagonal hole should not be harder than the material of the working part of the Allen key.

Original article in English

Share

Pin

Tweet

Send

Share

Send