Share

Pin

Tweet

Send

Share

Send

Will need

The basis for our universal furnace will be a metal tank with a lid and a crimp hoop.

We must also stock up on the following materials and accessories:

- a section of a profile square pipe;

- sheet metal;

- tin pipe;

- spray paint can.

Of the tools we will find useful in our work: a grinder with a cutting disc and grinding wheel, welding equipment, a plasma cutter, grinder, emery cloth, a drill and tongs for installing rivets.

Furnace manufacturing process

If the tank is new, then remove the o-ring, which will still burn when the furnace is kindled. The crimp ring will be useful for fixing the lid on the tank.

We cut off a piece of the required length from the profile pipe with a grinder, and from the sheet material - a segment in size close to the semicircle of the lid.

It is enough that it would be possible to place vertically profile and round pipes on it.

Mark the surface of the segment under a square neckline and next - under the round. We make a square hole with a grinder, and a round hole with a plasma cutter.

We make a polyhedron from a strip of metal sheet. To do this, on its inner side we make shallow transverse notches along the entire width and bend the strip until the opposite edges close.

The joint is welded.

We process the perimeter segment and cutouts on the emery wheel and grinder, removing burrs and cutting off irregularities.

Using the segment as a template, mark out the cutouts on the tank lid, which we then sell using a grinder.

At one end of the profile pipe we make a grate. To do this, we cut out narrow strips on the opposite sides of the grinder, which we remove, while the wide ones are tilted inward until they touch their ends. For better organization of combustion, the junction of the strips is shifted from the center, making the length of the strips, on the one hand, shorter.

On two adjacent sides of the pipe at the level of the grate, we make inclined slots for air to enter the furnace.

We install the profile pipe in the square hole of the segment and weld it at a certain level. On the same side of the segment we weld the polygon in place.

We put an exhaust pipe on the polyhedron and plant a fire in the firebox. Even in a furnace that is not yet completely ready, draft occurs and the fuel burns steadily, and the flame and smoke do not exit the furnace, but go down and fall into the chimney.

In order to remove paint and stickers from the tank, remove the lid, put it on top and light a fire to ignite its parts.

We process all surfaces of the tank and the lid with a cup wire circle fixed to the grinder spindle.

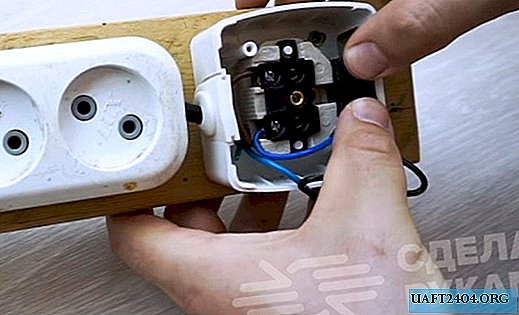

A segment with a welded firebox and a polygon is attached to the lid with four rivets.

After making sure of the riveting quality, we put the lid in place and fix it on the tank with the help of a crimp hoop.

On the side surface of the tank we drill with a drill a system of holes for air to enter the furnace.

Considering the depth of the tank and the location of the furnace, we manufacture a divider designed for such organization of flows in the furnace, which ensures its highest efficiency.

It is a single metal strip equal to the height of the tank, to which a horizontal plate is welded from below for stability of the structure. To a long strip at a right angle we fasten a short one, not reaching the bottom of the furnace.

We position the divider in the tank so that its plates do not touch the walls, but at the same time they separate the firebox from the entrance to the exhaust pipe and force the hot stream to move along a longer path in the furnace and give it almost all the thermal energy.

We put the cover in place and fix it with a crimp hoop. We paint the outer surface of the furnace with heat-resistant paint from an aerosol spray can.

We put the exhaust pipe in place, put firewood in the furnace and kindle them from the gas burner. After a short time, the stove will reach a stable combustion mode and will not only heat the room, but will also allow it to boil tea and even cook food.

Share

Pin

Tweet

Send

Share

Send