Share

Pin

Tweet

Send

Share

Send

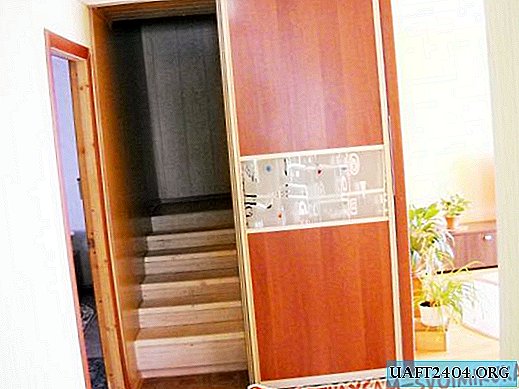

The classical (access) swivel staircase design with two straight flights optimally approached, since it occupies a smaller area and through it you can bring the necessary furniture.

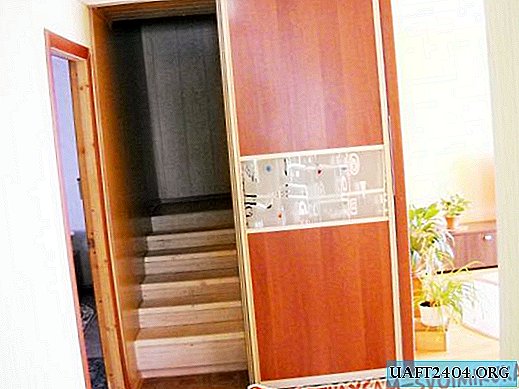

The walls of the corridor are made of wooden structures on three sides, so I decided to make a staircase without balusters and disguise it as a closet using the compartment mechanism as doors.

He completed the sketch, drawing with a marker a future staircase on the walls. The riser was 20 cm high, and the step itself was 28 centimeters.

When designing, I took into account the following:

- the slope of the stairs should be minimal for which it is necessary to increase the length of the march;

- steps should be at least 30 centimeters deep and strictly the same height so that they are easy to use and not injure;

- ensuring the reliability of the design, fixtures, adequate lighting;

- the implementation of the stairs with a width of 90 centimeters, according to the recommended standards.

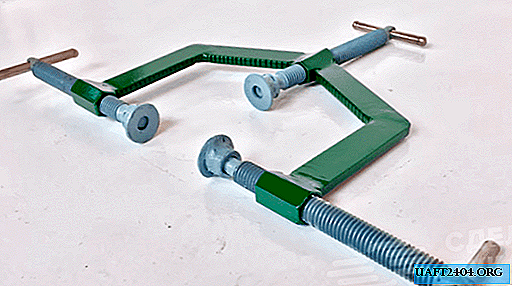

I performed the kosour of the lower march from a beam 60 mm thick and 30-35 centimeters wide. I made a bowstring for a kosour from a corner, pre-drilling holes in it every 10 centimeters on both sides, for attaching the kosour to the wall. This corner in conjunction with other metal structures served as the supporting frame of the stairs. The entire base of the upper march was also made from a corner, which he had previously sawed with an angle grinder and welded on the street. As a corner donor I used three old carapace beds.

For a two-flight staircase, he made a platform in the middle, fixing 40 mm corners to the walls, laying an old wooden door on them. On top, in addition to leveling the surface and giving greater strength to the site, I screwed a sheet of chipboard 90 cm wide. Subsequently, he lined the surface with laminated parquet, and covered the passages with a decorative corner.

The number of steps in the march, respectively, and its length of the march will depend on the height of the second floor. The steps will give the staircase construction not only additional strength, but they will not allow falling things to fall down and the air flow from the basement or pantry to walk.

For the material treads and risers, I chose a well-polished pine glued beam, which is sold in any specialized store.

The steps of the lower march were fastened with screws along the edge, and the upper ones from the inside into the holes prepared in the metal corner.

For the safety of the stairs and its strength, instead of the fence, I provided a solid wall between the marches. The entire finish above the flight of stairs was made by MDF panels, since it took into account that when you descend the stairs you have to touch the walls, and from this material it is enough to wipe them.

The staircase turned out to be very durable and quite comfortable, even for children, and using the compartment doors I veiled the presence of additional rooms and isolated the floors from each other so that the heat flow would not go up when the heating system was working.

Share

Pin

Tweet

Send

Share

Send