To work in a garage or a home workshop, you need a small lathe - so that you can process wood blanks?

You can make it yourself from a small grinder and improvised materials.

First of all, the author cuts two metal plates with a thickness of 5-6 mm. They need to drill holes. Then we fasten the blanks to the grinder.

From a piece of steel pipe, the author makes a clamping ring (or clamp).

The main stages of work

At the next stage, cut the workpiece from a piece of steel strip. The part will need to be welded to the mounting plates and clamp.

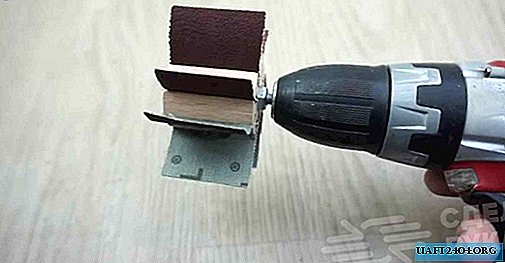

From a piece of a profile pipe or channel you need to make a bed of a lathe. In it, the master makes a longitudinal slot.

It will be necessary to weld the mount for the angle grinder to the bed (then we install the grinder itself).

From sections of metal strip it is necessary to make the tailstock of a lathe.

In the end, from a piece of strip, a round pipe and a corner, it remains only to make an adjustable handrail.

Then we clean the metal and paint. By the way, it is better to use a grinder with speed control.

For details on how to make a desktop wood lathe from angle grinders, see the video on the website.