In this review, we’ll talk about how to properly install a rivet nut. But first, let's figure out what they are and what they are for.

Also, probably, many of you will be interested to know how to choose the right rivet nut for specific types of work. Well, let's talk about everything in order.

A rivet nut is a type of fastener that is designed to be installed in products made of thin sheet metal in order to form a threaded connection in them.

It is not possible to cut threads in a thin plate with a conventional tap, therefore, a rivet nut is an ideal solution for blanks and products made of thin sheet metals

Rivets are distinguished by their shape. They are cylindrical, hexagonal or half-hexagonal, cylindrical with corrugation and even rubber.

What are the types of rivet nuts

The simplest rivet nut is a regular cylindrical rivet with a flat flange. Its peculiarity lies in the fact that it has a relatively small resistance to rotation.

In other words, when installed in the material, since it does not have corrugation, such a rivet-nut easily rotates inside the hole itself.

In order for the rivet to hold stronger after installation in the material, corrugation is done on it.

After installing such a rivet-nut, thanks to the corrugation, it is much better resistant to turning in the material.

If you need a rivet-nut that will maximally resist turning in the hole, then choose hexagonal fasteners.

There is also a special neoprene rivet nut, which is a collapsible element.

Conventional steel rivets, unlike neoprene, cannot be removed after installation - this is a non-removable fastener.

Which rivet nut to choose

Now let's figure out which rivet to choose for a particular material.

As in the case of exhaust rivets, for different types of material it is necessary to select rivet nuts from the same material.

It is necessary to use a steel rivet for a steel plate, a stainless steel rivet for a stainless plate, and an aluminum rivet for an aluminum plate.

By choosing the right size and material for the rivet nut, you can select the required load on your fasteners.

Accordingly, in order to choose the correct size and material of the rivet nut, you need to know the load on your connection and the fasteners that will be installed.

Features of mounting a rivet nut

In order to install a rivet nut in a metal plate, a hole must be made in the workpiece itself.

Depending on the type of rivet nut, the hole may be different. For example, for a conventional cylindrical rivet, a cylindrical hole is suitable.

For a hex rivet, a hole in the hexagonal shape must be made. However, such a hole can only be made with a special tool or on a laser machine.

Therefore, hexagonal rivets are usually used in industries where it is possible to make a hexagonal hole in parts and workpieces.

A hole of this particular shape is necessary so that the rivet is maximally protected from turning in the material.

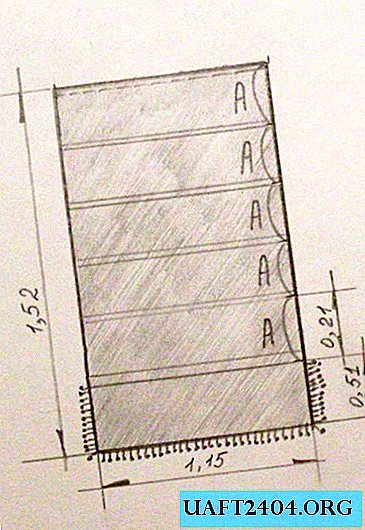

A very important point is the choice of drill in order to make the correct diameter of the hole for the rivet nut.

Each rivet has a specific outer diameter, and the drill must be 0.1 mm larger than this diameter.

Also, for certainty, you can consult the catalog of the manufacturer, because this indicator can sometimes differ slightly.

How to install a rivet nut in a part

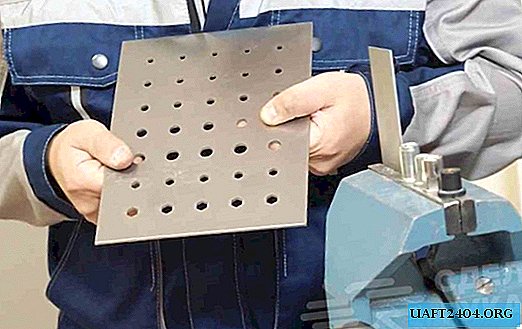

First of all, it is necessary to drill a hole of the desired diameter in the workpiece itself (let it be a steel plate).

To do this, you must first measure the outer diameter of the rivet nut. For example, it is 5.9 mm. Then you need to take a drill for metal with a diameter of 6 mm.

Before installing the rivet in the part, it is advisable to make a couple of rivets in the workpiece of the same thickness.

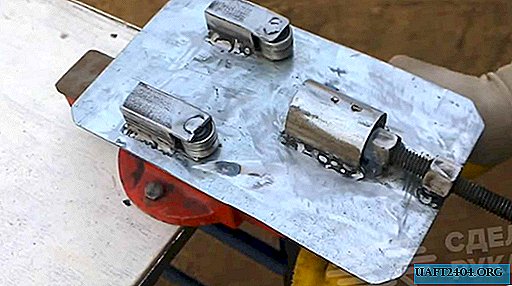

This is necessary in order to correctly set up the rivet gun, namely, it will be necessary to adjust the course of the rivet and the outreach of the stud.

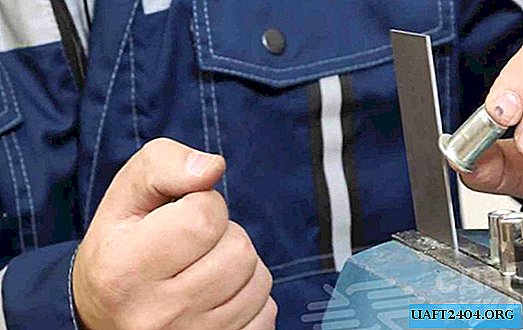

We wind the rivet (note that the pin should stick out of it literally a few millimeters), then we press the nozzle, and fix the nozzle.

Next, install the rivet nut in the hole in the steel plate, press the rivet firmly against the material with the flange and strictly at an angle of 90 degrees, without deviating horizontally or vertically, we begin the installation of the rivet.

For details on how to properly install a rivet nut with your own hands, see the video on our website.