Unlike a stationary grinder mounted on a bed, the possibility of a manual grinder is much less. With it, you can sharpen knives and tools or process small parts and workpieces from metal.

In this case, the author decided to make a manual grinder based on a small grinder. However, it is advisable to use a angle grinder with a speed control for this purpose.

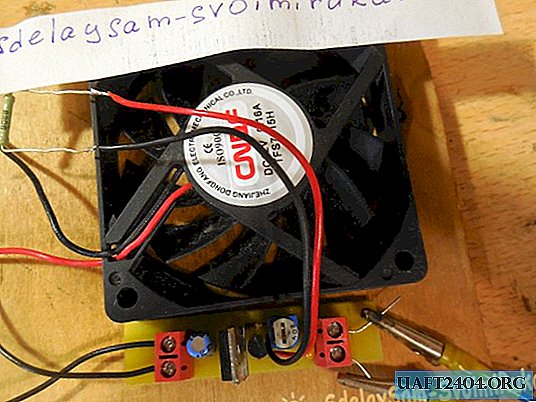

The first step is to press the elongated nut into the metal sleeve. The author does this with the help of yews.

After that, we wind the drive roller onto the shaft of the gearbox with the angle grinder. See the photo below.

The main stages of work

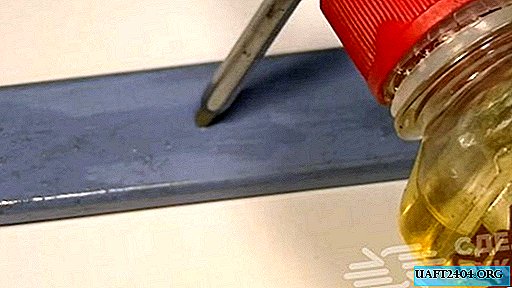

At the next stage, you will need to prepare two sections of the profile pipe 20x20 mm and 15x15 mm, as well as a piece of spring. The profile 15x15 mm and the spring will then be inserted into the profile pipe 20x20 mm.

The author fastens a pair of bearings to a short section of the 15x15 mm profile. To do this, you will first need to make “ears” at the end of the profile, and then use bearings and nuts to secure the bearings.

Next, from a piece of a round metal pipe and two nuts with a bolt, it will be necessary to make a clamp for the grinder. The clamp must be welded to the profile of 20x20 mm.

In the end, it remains only to connect all the parts together, and glue the sanding belt of the desired size or you can buy ready-made.

For details on how to make a manual grinder from a small grinder, see the video on our website.