To make your own cool bench vise for a workshop, you need a corner of 70 * 70 mm, a stud with a diameter of 16 mm, a pair of washers and a thrust bearing.

First of all, from the pieces of the corner, the author welds the channel. Ideally, of course, use a ready-made channel, but if it is not at hand, then, as an option, you can get by with a corner.

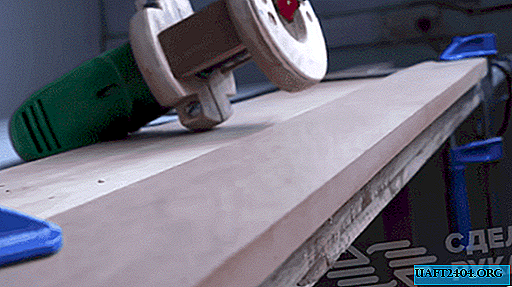

After the channel has been welded, the place of the seam will need to be cleaned with a grinder. Further, the author is engaged in the manufacture of other blanks, which he will use in the process of creating a vise.

The main stages of work

After all the main parts are ready, you can proceed directly to the assembly. First you need to weld the nut to the platform, and then to the bottom of the vise. And then we weld the plate with the hole for the screw.

Then the master drills holes and cuts the thread for the so-called slide. After that, it will be necessary to weld the rest of the workpiece.

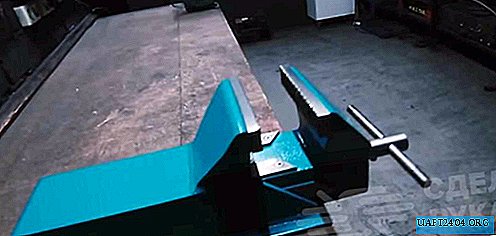

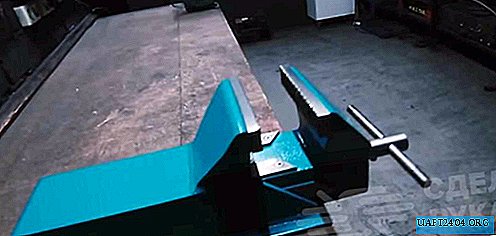

Then we drill holes in the jaws and cut the threads into them. After installing the jaws, we weld the remaining parts and clean the metal with a petal circle. In the end, it remains only to weld the mount to the base.

Then the vice will need to be painted. For more information on how to make a bench vise from a building corner and thrust bearing, see this video.