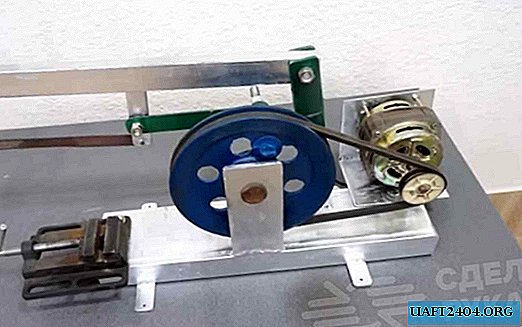

As an alternative to the grinder and the cutting machine, the master decided to make a desktop electric saw for the home workshop (and garage). If you are interested in this idea, you can make such a device from improvised materials.

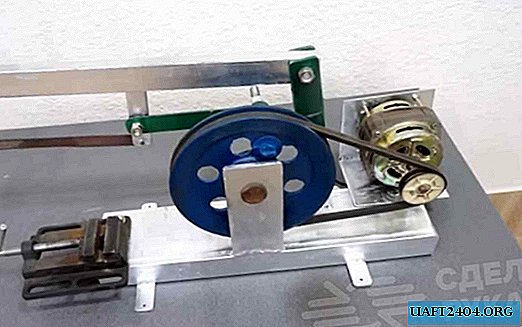

One of the main structural elements is a large diameter pulley. As the base, a piece of the channel is used.

The first step is to make the pulley mountings from the metal plate. They are welded on the sides of the base (channel). Next, from the sheet metal, you will need to make a base for the electric motor.

The main stages of work

After finalizing the platform for the electric motor (by the way, in this case, the master uses the engine from the washing machine), the drive is installed on the base.

Using a rubber belt, the motor pulley connects directly to the large pulley.

Next, the master makes and installs on the base a movable shoulder node from two segments of the profile pipe. A bolt hole is drilled in a large pulley. Then the installation of the main parts.

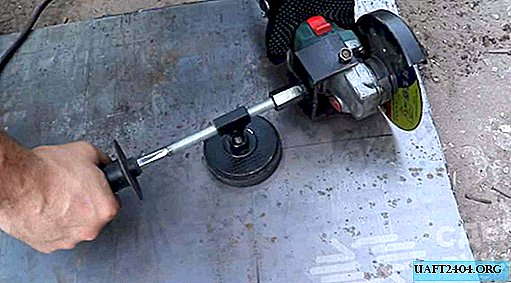

At the last stage of work, fasteners for fixing the saw blade are made from a metal strip. Then all the structural elements must be cleaned with a grinder, and then painted. Next, the final assembly is performed.

For details on how to make a do-it-yourself desktop electric saw for a home workshop or garage, see the video on our website.