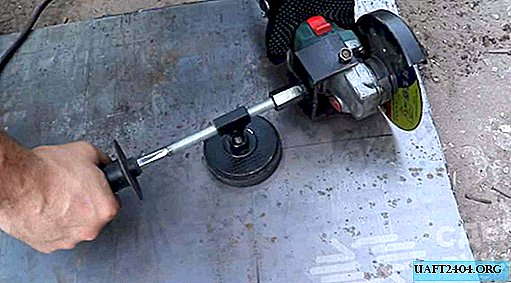

Cutting an even round hole in sheet metal using a grinder with a cutting disc, holding it in your hands, is very problematic. For a beginner, such a “trick” will definitely not work.

In this review, the author suggests using a home-made magnetic “compass” for an angle grinder. For the manufacture of this device mainly used materials are used.

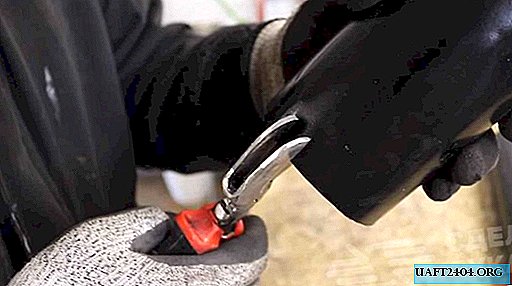

First of all, we separate the magnet from the speaker housing. Then we disassemble it: we get two plates and the magnet itself.

For the manufacture of homemade need a plate, which is with a core. We clamp it in a vice and cut off the core with the grinder almost flush.

The main stages of work

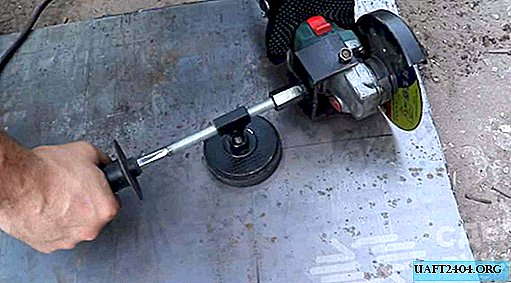

In the next step, you will need to glue the magnet to the plate. For this, the author uses cyanoacrylate glue.

After that, you need to cut off two pieces of a corner 40 mm wide and weld them together. Then, an elongated nut must be welded to the resulting part. Drill one hole in the side walls.

To the plate glued to the magnet, you need to weld a nut. We screw a bolt into it, to the cap of which it is necessary to weld a perpendicular elongated nut.

And at the last stage, it remains only to make another part. We weld an elongated nut to a piece of a stud (at the end).

Then all the details must be painted, and you can already proceed to the assembly. For more information on how to make a magnetic “compass” for an angle grinder, see the video on the website.