Surely, every home has outdated appliances. She can still serve and work, but she has a more convenient and modern replacement. Someone simply throws it into the scrap, while others find it more worthy of use.

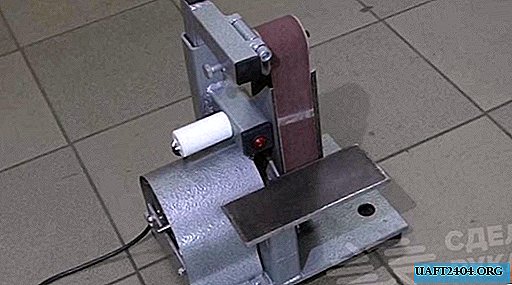

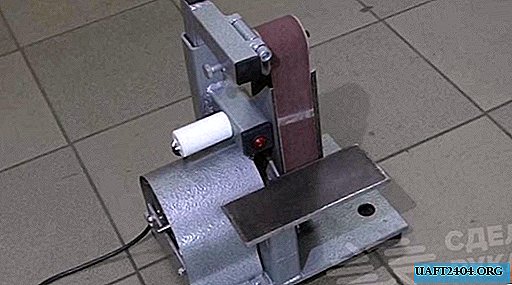

For example, an electric motor from an old washing machine can be used to create a mini-grinder (belt grinder).

The versatility of just such an electric motor lies in the fact that it works from a 220 volt network and does not need to be converted from 380 volts to household voltage, as well as in sufficient power and medium revs, which is very convenient when designing various devices.

The main stages of work

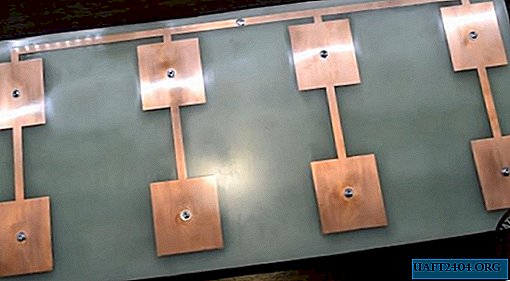

First of all, the author makes the rollers on which the sanding belt will be worn, using the most affordable materials and tools. For the manufacture of the leading and two driven rollers, plywood is used.

Next, the tensioner, housing, bed for the machine and the protective cover for the engine are manufactured. All parts are made of materials available to everyone. For the manufacture of a protective casing, the washing machine body is used, and the author decided to take a furniture gas shock absorber as a tensioner.

The saved ruble is the earned ruble. Having spent a couple of thousand rubles on this grinder, the author saved a lot more by not buying a new machine. For details on how to make a mini-grinder for a garage from an engine from a washing machine, see this video.