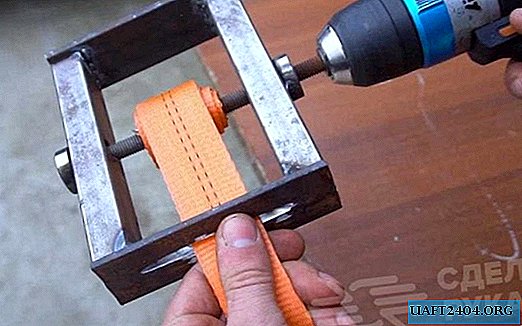

To make this nozzle, it is necessary to cut off two pipe blanks with a rectangular profile with a grinder. Two pieces of 20 cm long are enough. It is also necessary to cut two plates with a length of 15 cm.

Workpieces must be machined and deburred. Sections of profile pipes are welded to the plate. It is necessary to check that the angle between the base and the posts is 90 degrees. A plate is also welded on top.

Thus, a frame for the future nozzle is obtained. Further, in the resulting frame, it will be necessary to make coaxial holes. 2 bearings are welded to them from the outside. In the plate, the master makes a groove for feeding the rag belt.

The process of manufacturing nozzles for electric drill

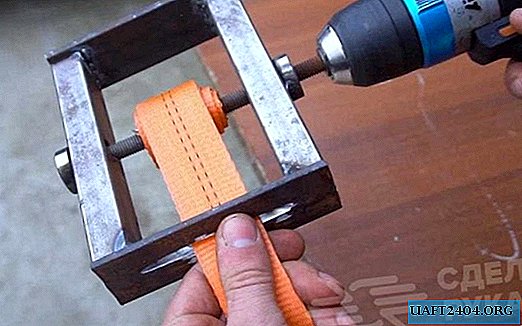

A pin is inserted into the resulting holes. Its diameter should correspond to the diameter of the bore and the welded external bearings. One end of the stud is inserted into the electric drill chuck. Homemade rag belt wrapper ready.

What are the advantages of making a DIY nozzle for a drill? First of all, the cost of such a homemade product is much cheaper than the cost of a factory analogue. It’s not a fact that the purchase option will be better than the one you make yourself.

It is important that you can make an improvement on the nozzle depending on your goals. With this device you can wind not only belts, but also tapes for various purposes.

For details on how to make a homemade nozzle for a screwdriver or an electric drill for winding rag belts, see the video on the website.