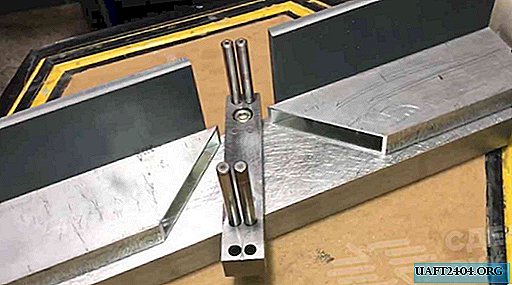

Unlike classic F-shaped or G-shaped clamps, quick-clamps are more convenient to use. Especially when you need to process a large number of workpieces in streaming mode. And you can make a quick-clamp clamp with your own hands from a strip and a square.

For this homemade product you will need two pieces of strip width of 40 mm and a thickness of 5 mm, as well as a steel square of 20x20 mm. The sizes are arbitrary - if desired, you can use the profile and square of another section.

After two blanks are cut from the strip, we retreat from the edge of about 1-2 cm and make a square hole in this place. First you need to make markup with a marker using a square bar. First, we drill holes in the corners, and then we cut through the "window" with a drill.

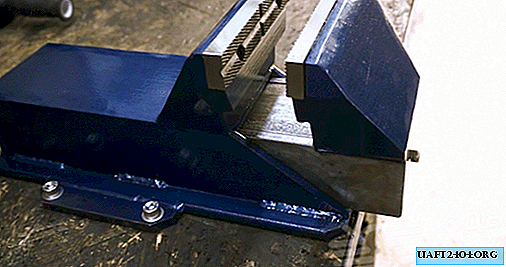

The process of making a quick clamp

After making a hole, we process the edges with a file for metal. Then we clamp the workpiece in a vice and bend it a little with the blows of a hammer. We weld the square to the base, then we put a blank with a hole on it from above.

On the other side of the base you need to weld a clamping sponge cut from a piece of a plate 5 mm thick. We weld the upper clamping jaw of the clamp to the stud, which we fasten to the upper metal strip. We put a spring on the stud.

For details on how to make a quick-clamp clamp from a steel strip and a square with your own hands, see the video on the website.