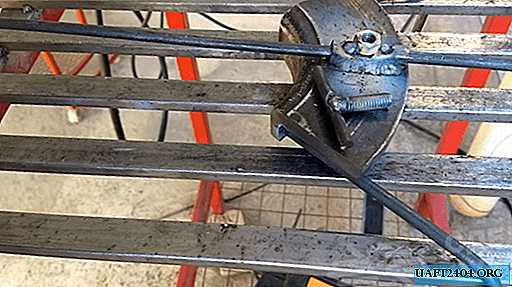

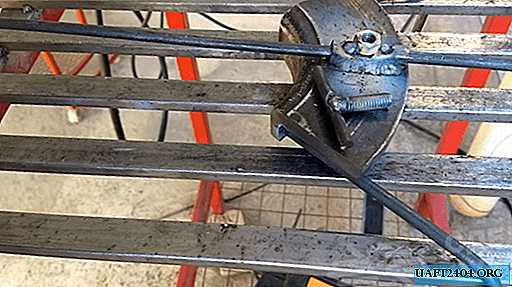

In order to smoothly weld together small parts and various metal blanks, it is necessary to correctly set and fix them. To do this, a simple fixture called the "third hand" of the welder is useful.

You can make it yourself from an automobile brake disc and steel bar. Using this device for welding, you can quickly and accurately fix parts or structural elements in the desired position, while both hands remain free, which is very convenient.

Homemade holder has a fairly simple design. The brake disc acts as a support and base, while the bar itself is used as a "finger". Moreover, depending on the model of construction, the “fingers” of the third hand can have from one to several pieces.

The main stages of work

First of all, we pick up an angle grinder with a cutting wheel and cut off a piece of a suitable size from the brake disc of the car (approximately 1/3 of the entire disc).

Next, cut off a piece of steel bar and sharpen one of its ends on a grinding machine or using a grinder with a flap wheel. Then the upper part of the workpiece must be bent with the letter "G".

Then, a small piece of the profile pipe should be welded to a piece of the brake disc, which will be used as a guide for the “finger”. Drill a hole on top of the profile and weld a nut. We screw a clamping bolt into the nut (or you can use a stud with a knob).

At the edges of the base, additional support elements must be welded to ensure greater stability. The manufacturing process of the "third hand", see this video.