The peculiarity of this metal frame is that the seat with backrest, as it were, spring under load, thus providing additional comfort. For the manufacture of a metal frame, a steel pipe of circular cross section with a diameter of 20 mm and a profile of 20x20 mm will be required.

Design features

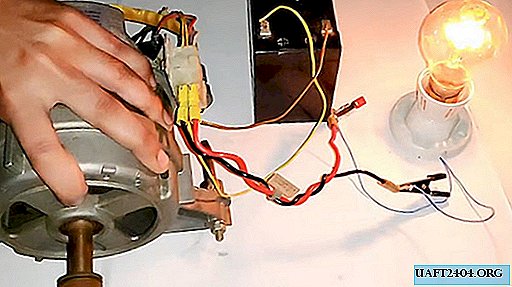

The legs of the chair frame are not ordinary, but made in the form of a spiral - they gradually bend and smoothly pass into the armrests. Then, a seat with a back is attached to the lower edge by electric welding.

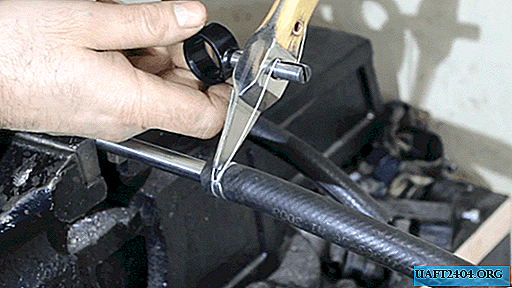

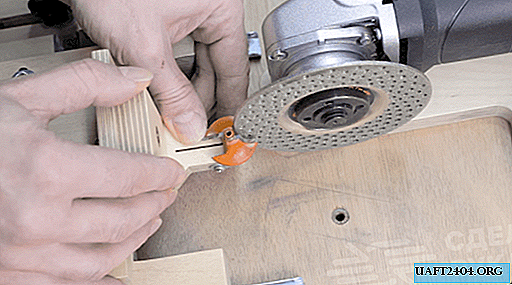

Please note that after rolling a round steel pipe on a pipe bending machine, it becomes slightly flattened, and therefore successfully harmonizes with the profile shape of 20x20 mm. The bent legs are first welded to the bent spiral workpieces (they must first be sized).

The side parts of the metal frame are interconnected using four jumpers. Then the seat with the back is welded - on this the frame is completely ready. Then only the frame will remain with wooden battens or soft upholstery.

To summarize

Sitting in such a chair will be very convenient, since the "spring effect" softens the fit and makes it more comfortable. If necessary, the armrests can be lowered a little. A detailed process of manufacturing a metal frame of a chair from a steel round and profile pipe can be seen in the video on the website.