Factory grinding machines are not cheap, so if you have a working electric motor at hand, you can make a homemade unit that is ideal for a small workshop, summer house or garage. As a drive, it is recommended to use a 220 V engine, which produces at least 2700-2800 revolutions.

The main stages of work

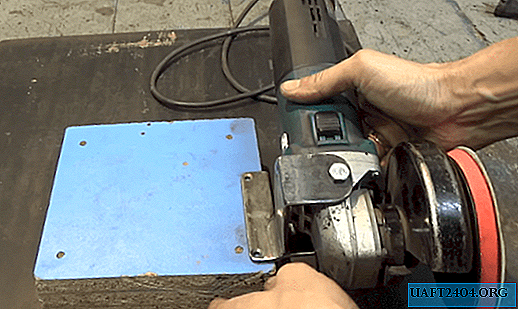

The first step is to make a frame for the "landing" of the electric motor. To do this, cut a piece of suitable size from a sheet of metal. On the edges we drill holes for bolts for fastening to a wooden / metal workbench or table.

Then you need to make a vertical stand - for this, cut a piece of the profile pipe that is suitable for the length, grind the edges and weld it to a metal base at an angle of 90 degrees. Please note that the profile pipe should be in the middle of the plate.

At the next stage, from the pieces of a thick steel plate, you need to weld a “shoulder”, which is attached to the profile at a right angle. This structural member is then inserted into the upright.

Machine assembly process

At the base of the machine four holes are marked and drilled for installation of an electric motor. A rectangular plate is screwed to the body, which is used as a desktop. A big drum is put on the motor shaft, and a small one is attached to the "shoulder".

The result is a compact grinding machine that can be mounted on a table or mounted on the floor. See the video on the website for the step-by-step process of manufacturing and assembling a homemade belt sander for a home workshop.