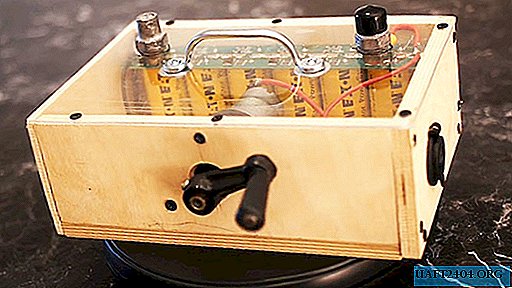

From a conventional electric motor and improvised materials, you can assemble a practical and very convenient to use budget option of a home-made grinding machine for a home workshop or garage. At the same time, the obvious advantage of this homemade product is its lower cost compared to factory models.

A rigid circle of plywood is mounted on the motor shaft, on which the sandpaper is attached. Despite all the simplicity of the design, the grinding machine for the home has quite good functionality. With it, you can process wood and metal workpieces, as well as produce various parts.

Grinding machine manufacturing process

First, cut a circle of suitable diameter from a sheet of plywood. In the center of the circle, you need to drill a hole to fix it on the motor shaft. We also drill four holes for the bolts. For rigid fixation in the drilled holes we cut the thread.

Then it is necessary to cut another round billet of the same diameter from a plywood sheet and glue two halves of the grinding wheel using ordinary carpentry PVA. Then you need to drill a central through hole in the glued circle and make four recesses for fasteners.

Also from plywood we make a box for an electric motor and a work surface. After complete assembly of the body part, the home-made grinding machine is ready for use. No gearboxes and belt drives are required here, since the effort in the process is relatively small, the rotor axis can cope with such a load without problems.