Share

Pin

Tweet

Send

Share

Send

To work, you will need:

• Old newspapers or newsprint.

• An ordinary knife.

• Thin knitting needle.

• PVA glue.

• Food colorings.

• Colorless varnish

• Brush for processing the finished product.

A step-by-step description of the manufacture of the casket.

1. The direct weaving of the casket will be carried out from newspaper tubes, which will require approximately 200-220 pieces. In order to get a newspaper tube, you need a newspaper or magazine, using a regular knife, cut across into strips, the width of which is about 5 cm. If tubes of darker colors are planned, you can use a newspaper. For tubes of light and bright colors, newsprint should be used, since letters may be visible during painting.

2. In order to make the tube long and neat, the needle must be used as thin as possible. A needle is placed on the edge of the newspaper strip at an angle of 35-40 degrees. The smaller the angle, the thinner the tube. From thin tubes, the product is more accurate and gentle. Tightly pressing the edge of the paper to the spoke, you need to twist the tube. Lubricate the remaining upper edge with PVA glue and screw the tube to the end. Pull out the needle. The tube is ready.

3. You can use stain and food coloring to paint the tubes.

To paint with stain, just drop the tubes into the bottle with this solution and immediately remove it. Leave to air dry for 3 hours.

To paint the tubes with food colors, it is necessary to dilute them according to the instructions and lower the tubes into the container with paint for 5-7 seconds. Dry in a warm place until dry.

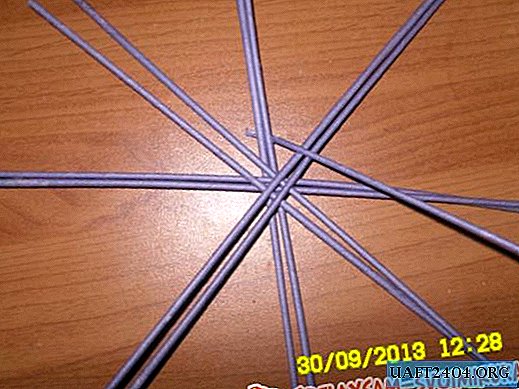

4. For weaving the bottom of the casket, you need 4 groups of tubes, 2 in each, to lay a cross - crosswise on top of each other. These tubes are called risers.

5. Under the lowest group of tubes, substitute 1 working tube and braid each group in turn.

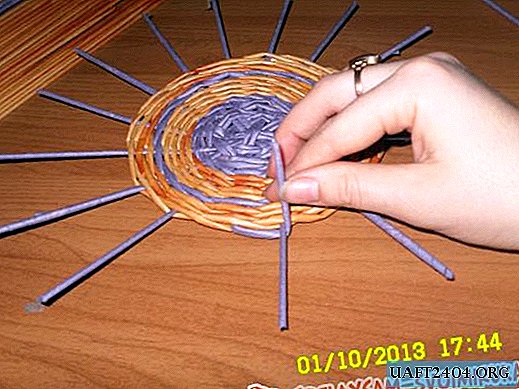

6. In order to increase the working tube, it is necessary to fold the next edge in half and insert it into the working one. There is no need to glue anything.

7. After the 6th-7th row of weaving, the risers must be divided so that 8 single ones (out of 4 groups) are formed. Substitute similarly to the first one, another working tube. Next, weave the product "rope". To do this, grasp the riser from above with the first working tube and the bottom from the bottom. The second stanchion is braided in the same way, only the tube that was on top will go down and the bottom up.

8. After the bottom of the desired diameter is ready, the working tubes must be glued, and after drying, carefully cut.

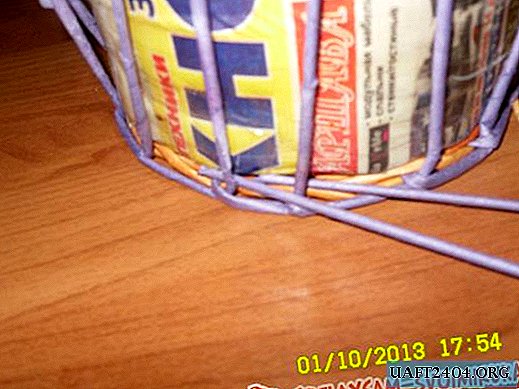

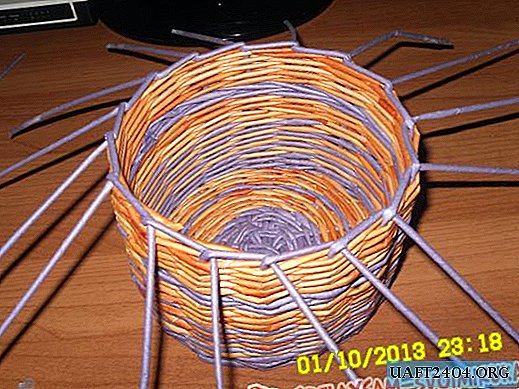

9. For weaving the walls of the casket, it is necessary to raise the risers up. To do this, we start one riser from below under the nearby one and carefully raise it up. We are doing the same work with the rest.

10. If necessary, increase the stanchions.

11. Insert the mold into the product. When using it, the product will turn out more accurate and even. Substitute 2 working tubes.

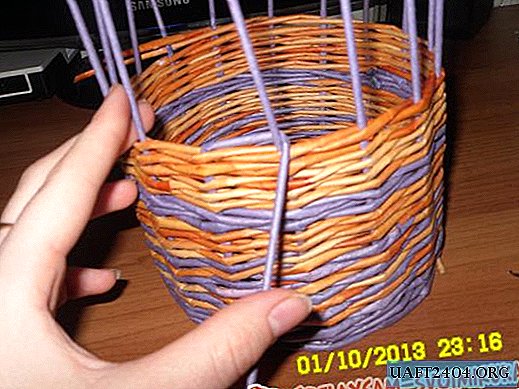

12. Weave with a "rope" 2-3 rows. In order to get a pattern, 1 working tube must be replaced with a different color. Then weave out according to the intended pattern.

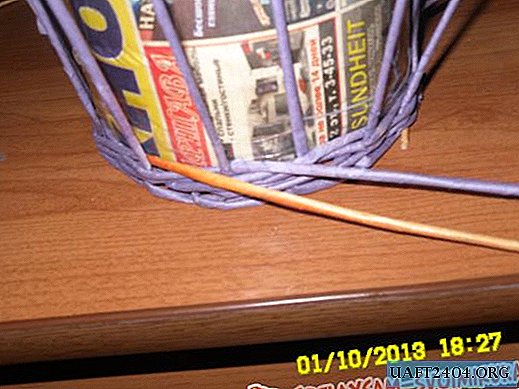

13. After completing the weaving of the casket wall, glue the work tubes and cut them off.

14. Bending.

Start the first stanchion from the inside behind the second and round it. Start the second for the third. And so on until the end of the row.

15. Next, we introduce the tip of the first riser into the formed hole, after rounding the second, next to the first. Perform this manipulation with all risers. Gently glue from the inside, and after complete drying cut off.

16. The lid is woven exactly like the bottom. At the end, bending is performed.

The lid can be decorated in accordance with the desires and imagination.

17. The finished box is varnished, which will give it shine and strength.

Share

Pin

Tweet

Send

Share

Send