Share

Pin

Tweet

Send

Share

Send

Today we offer an improvised version of such miracle insoles with electric heating. Their design will help keep your feet warm for quite some time. They dry out in just a few minutes, and maintaining a stable temperature will prevent ordinary insoles from getting wet from small cracks in shoes.

The principle of heating the insoles

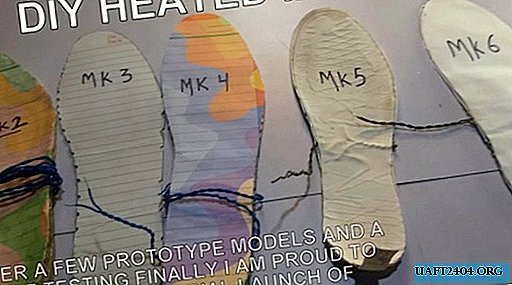

In his invention, the author decided to dispense with a heating element based on a copper wire with a varnished coating, used for windings of transformers and various inductors. Having experimentally calculated its length relative to the supplied voltage of the batteries, a heating platform was made under the main coating of ordinary insoles. The insulation layer between the insole layers is made of hot glue. The button-switch with batteries are mounted in the area of the laces on the tongue of the shoe.

The necessary elements and tools for homemade

Materials:

- Copper wire;

- Insole pattern;

- Thin cardboard, paper;

- Batteries - 2 pcs;

- Connector - a socket for connecting power;

- Wire cutter and stripper;

- Button switch;

- Universal diode;

- Wires, thermocontractable cambric small, insulating tape.

Tool:

- Soldering iron;

- Hot glue gun;

- Scissors;

- Nippers.

Insole manufacturing process

Cut out the insoles

The device is a multilayer insole, the lower part of which is a heating platform. For her we need a thin thick cardboard. He must withstand walking, so it is better to choose something more resistant to abrasion.

We take the template of our insole, and mark the platform on it. It should be approximately one size smaller than regular insoles. We process the edges of this insole platform with a hole punch around the perimeter. This will additionally fix the heating element, and will not allow it to slip while walking.

We wind the heater winding

The intensity of the wire winding controls the heating value of a specific zone of the heater-insole, and it can be calculated individually. The author marked the insole so that the maximum heat falls on the toe, the middle on the heel, and the lowest - in the middle of the foot. In accordance with the selected scheme, we wind the turns of the heater winding by measuring the length of the wire 10 m.

We mark the protective layers of the heater on plain paper according to the template and cut them out. On both sides we glue the heating platform with paper insoles on hot glue.

Do not forget to bring the ends of both contacts of the winding out. We connect them with insulated wires, solder the connection and seal with heat-shrinkable cambrics.

We supplement the circuit with batteries with a power socket and a button

We connect the batteries, connecting them in parallel with the soldered contacts. We glue the battery cases on electrical tape.

The switch button with a diode and a power socket is soldered according to the scheme (photo 2). We place them on the battery case, and hide them in several layers of electrical tape.

We insert the heating platform into the inside of the shoe, and cover it with ordinary insoles. The author suggests hiding the battery case between the laces and the tongue of the sneakers.

Control measurements

As practice shows, the device is capable of producing pretty good indicators. For a heating element that can warm shoes without harming the foot and material, this is more than enough.

Heated insoles are ready, you can safely take them on a campaign in the cold season, without fear of freezing your legs, and damaging your shoes.

Practical tips

The value of any invention is its long-term use, and thin cardboard and paper are not a good basis for the heating element of the insoles. Chinese counterparts based on copper foil also do not shine with durability, breaking on folds due to constant excesses.

The blame for the weak base and the fragility of the heater

These materials can be replaced with artificial leather, felt, lavsan, etc. And instead of copper wire, use nichrome or carbon fiber for warm floors. Insulation of the heating element also does not hurt, and the batteries, the ability to adjust and turn off the heating can be brought closer to the hands. In general, there is something to work on.

Such homemade products are valuable for lovers to craft with their own hands. They can be redone, modified and changed at your discretion, taking on the basis of the principle of the device. Otherwise, each home master has a free path to creativity and his own discoveries.

Share

Pin

Tweet

Send

Share

Send