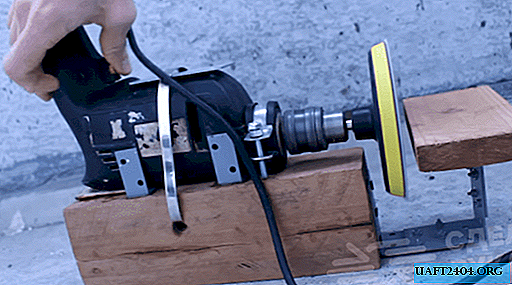

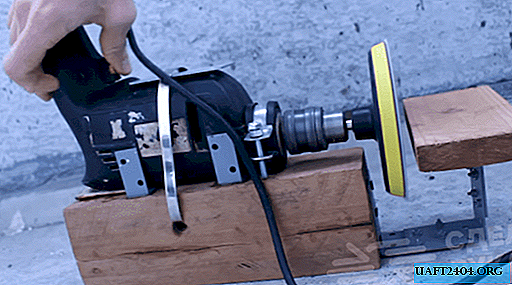

For grinding small parts it is convenient to use a small grinding machine, which can be made from a household electric drill. Also, for work you will need three large (40x60 mm) and four small (40x20 mm) corners, a metal clamp, a mount for mounting plastic pipes with a diameter of 45 mm.

As a base, a wooden block of 100x100 mm is suitable. A work table for a grinding machine can be made from a piece of board or plywood. Also for this homemade product you will need a regular grinding disc with Velcro with a diameter of 125 mm.

First of all, we connect three corners of 40x60 mm with bolts and nuts. A drill or grinder needs to be cut off the excess part. We also trim the small corners of 40x20 mm a little. Saw the size of a wooden block (along the length of the drill with a margin) and a piece of board.

Grinding machine manufacturing process

In a wooden block with a stepped or feather drill, we drill a through hole so that the drill itself can be fixed with a metal clamp. You also need to drill one blind hole - for the installation of fasteners for plastic pipes. It is necessary to fix the "neck" of the drill.

Then the wood blanks must be sanded and painted with stain or colorless varnish. Next, proceed to the assembly. We pass a metal collar through the through hole, and into the blind one we sit on the epoxy the lower part of the mount. On the sides of the bar we fasten the corners of 40x20 mm.

At the last stage, we install an electric drill with a Velcro disk, after which we fix the working table. The step-by-step process of assembling a grinding machine from a household electric drill can be seen in the video on the website.