In the process of repair and construction work in a private house or in a summer cottage, it is often necessary to bend a profile pipe under a certain radius. For this, special roll forming machines are used.

With their help, you can bend the profile of a rectangular or square section of different thicknesses. Factory models cost a lot of money, so for home use you can make your own budget option profilegib.

The main stages of work

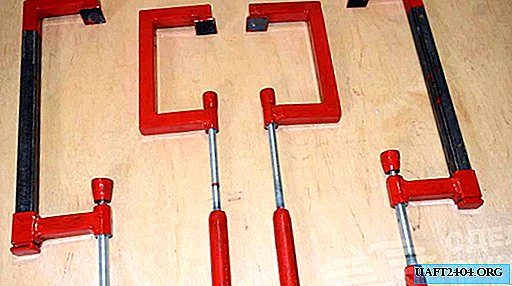

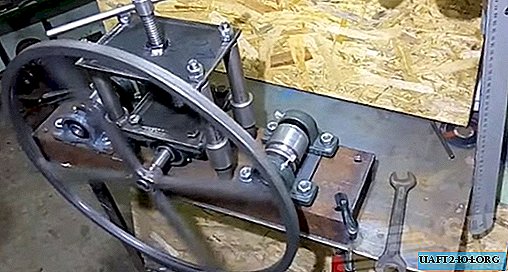

As the base of the profile bending machine, you can use a piece of channel 600 mm long and 140 mm wide. Along the entire length of the base, 2 pairs of case bearings are installed, four vertical posts are fixed between them, which can be turned on a lathe.

In the central part of the channel two plates are mounted (one above the other). The bottom plate has dimensions 140x140 mm, and the top one is 140x200 mm, it rests on steel "barrels", and a hole for the clamping screw is drilled in the center of the plate.

Machine assembly process

We make markings and drill holes for mounting housing bearings and uprights. Then the “docking” of the main structural elements is carried out, the lower plate is welded to the bushings.

A third pair of housing bearings is attached to the bottom of the plate - a shaft with a handle is inserted into them, with which the profile tubes are rolled. The bending radius is regulated by the clamping screw. For a detailed process of manufacturing and assembling a home-made roll forming machine, see the video on our website.