The magnetic holder is a simple but very useful device that you can not do without when performing certain welding jobs. Using this angle, you can quickly and most importantly - precisely fix the workpiece at an angle of 90 degrees.

Structurally, the device consists of three sections of a profile pipe connected together by electric welding at an angle. Between them is a round magnet from the old speaker.

A welding square is used in the process of working with pipes, strips, corners, profiles, and also sheet metal blanks. It is inexpensive, but why buy when you can do it yourself? Moreover, materials for work are almost always at hand.

The main stages of work

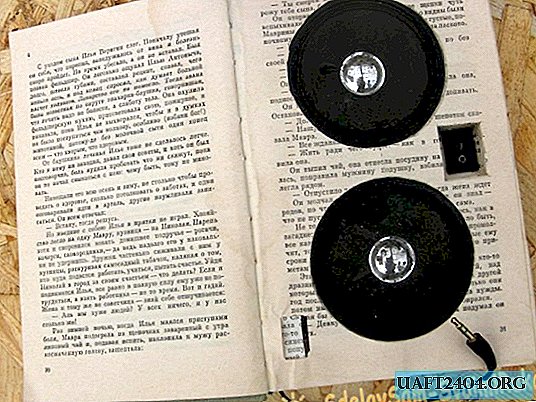

First you need to use a hammer and a chisel to separate the magnet from the old (better than Soviet) speaker. Then remove the steel plates on the sides. The result is a solid round magnet that will become the basis of the welding square.

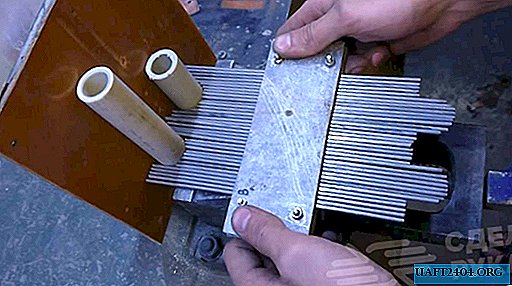

At the next stage, we make the necessary marking for the "seat" for the magnet and cut out three blanks from the 40x40 mm profile pipe, which are then welded together in the shape of a triangle (the magnet should be inside the entire structure).

It is desirable to clean the surface and places of the welds with a grinding disc, and then paint it to protect it from corrosion. The result is a home-made magnetic corner (holder) from the profile, which is useful when welding workpieces at an angle of 90 degrees.