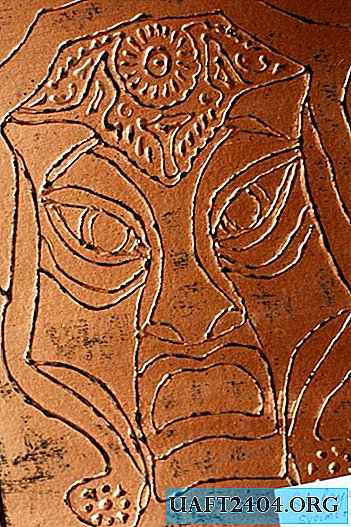

In the arsenal of any self-respecting carpenter carpenter, there must be a hand-held bracket, which is a large knife with two handles. This tool is universal, and therefore you cannot do without it in the workshop. A skobel is often used for planing (for example, instead of planers) or to quickly remove bark from a log or log.

In general, the yoke can both "drive wood chips" in the process of processing a wooden billet, and remove fine chips from it. But for this it is important that the steel of which the tool is made is of good quality. Therefore, the use of a bearing for this purpose is an excellent option.

The process of manufacturing a hand brace

Clamp the bearing in a vice and cut the outer ring with a grinder. We heat it red-hot, unclench and take out the “filling” - the inner ring with balls. Then we transfer the round billet to the anvil and with the help of a sledgehammer we level it, giving the form of a strip.

At the next stage, we form the working part of the tool (the knife itself) and the handles at the edges in the form of an elongated cone. The handles themselves are slightly bent. Next, we carry out the procedure of steel hardening: we heat it red and lower it into a container with oil.

We process the workpiece for staples on a belt grinding machine, form a cutting edge and remove irregularities. We make two wooden handles and put them on the edges of the tool. The brace is now ready for use. Thanks to a one-piece construction with handles and a low profile, excellent control over the woodworking process is ensured.