To accurately drill a hole in metal workpieces (for example, steel, bronze or brass), it is extremely important to make a competent marking on the surface of the parts. And the key to success in this case is proper punching.

Some craftsmen use the factory standard core for this, others - the usual dowel-nail. Both methods are good, but they do not always give the perfect result. To avoid errors in the marking process, it is better to use a spring core, which can be done with your own hands.

Manufacturing process

It is desirable to use a steel or bronze bar as the basis, and a spring of about 60-100 mm in length is also required (it is better to use a not very rigid one). The firing pin can be made from an ordinary dowel-nail.

In a steel or brass bar, it is first necessary to drill a hole in the center with a diameter of 4.5 mm, into which then the trimmed end of the dowel-nail will need to be hammered.

If your home workshop does not have a lathe, then you can use a conventional electric drill and drill to trim the part and drill a hole. The principle of operation is extremely simple: the workpiece rotates in the drill chuck, and the drill disc is used as a cutter.

The final stage of work

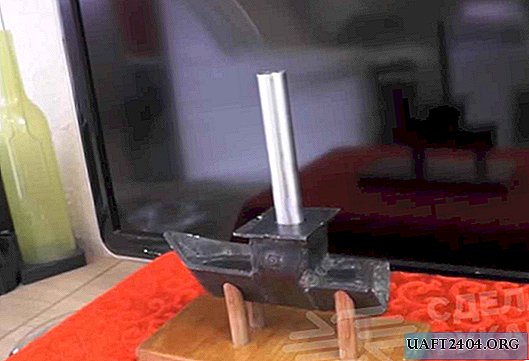

When all the preparatory work is completed, you can begin to process the outer surface of the workpiece. Then you need to hammer the trim of the dowel-nail into the hole in the bar. In order not to immediately spoil the sharp tip, it is better to do this work on a copper anvil.

On the reverse side of the bar you need to make a flat cone so that the spring is easier to put on. After putting on the spring, you need to grind the core shank. After fixing the tail, the tool is ready to use. A spring core will allow you to avoid gross errors in the process of marking.