Share

Pin

Tweet

Send

Share

Send

Materials and Tools

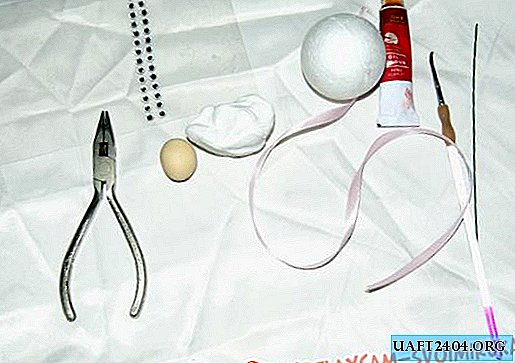

For the manufacturing work you will need such materials:

• three sheets of laminated particleboard;

• washers;

• nuts;

• hairpins;

• hexagonal blind nuts;

• chrome tube;

• furniture wheels.

The material for the manufacture of tables may vary from the preference of the owner. In this case, the countertops are made of laminated on one side of the cushioning material for the laminate. You can buy it at any hardware store by contacting the sellers. Another option is to ask for sheets in warehouses storing building materials. In this case, you can save a lot of money.

Tools required:

• jigsaw;

• grinder;

• screwdriver;

• wood drill based on the diameter of the stud;

• roulette;

• set of wrenches.

If there is no jigsaw in the farm, it’s not a problem. Currently, the service of cutting materials is widespread. At a moderate cost, they will make a cut according to a given drawing or even help with a layout.

Manufacturing process.

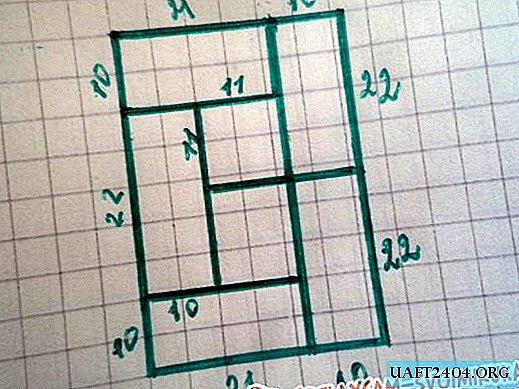

First, the sheets should be packaged and fastened with clamps. In this form, they are given the necessary form. A pattern can be a pattern from an aracal superimposed on the top sheet of a pack. All work should be done on the rough side of the sheet.

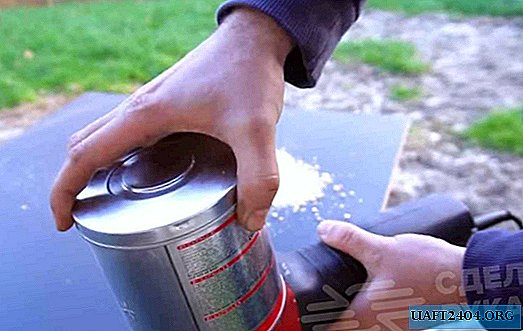

After shaping the sheets, the distances for arranging the holes for the studs are marked. They should be at least 5 cm from the edge. Drilling takes place without removing the clamp. The length of the studs is 1 m. Coffee tables for the living room are not made high, because the studs are cut in half by a grinder. In this case, you need two products for installation. Chrome tubes are sold three meters long. Their size is determined based on the distance between the countertops. Do not forget to subtract the thickness of the middle countertops and washers.

Stage One

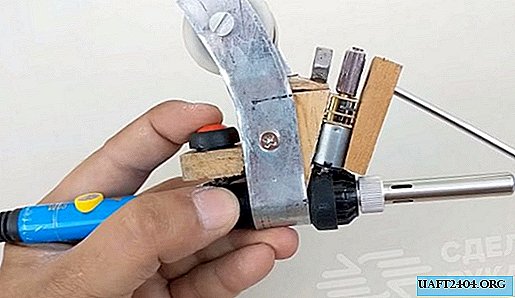

Take the top cover and lay it face down. We put a hairpin in the holes. The washer is arranged on the front side, with a flat surface to the canvas. We fix the hairpin with a blind nut.

On the other hand, a washer with a skirt is screwed onto the stud.

The assembly of the table assembly with your own hands looks like this:

The wrong side of the lid turned out like this:

A chrome tube is put on the hairpin. It serves as a decorative element. Backlash is eliminated due to the size of the nut.

Second phase

On a washer arranged on a chrome tube, a second countertop is put on. The design is fixed with nuts.

Third stage

Holes under the wheels are drilled in the bottom countertop. They are arranged inside the structure from the holes for the studs. Since the table according to the individual dimensions of the hole for movable elements can be arranged without marking - by eye.

Furniture castors are fixed.

The bottom countertop is fixed to the structure.

The stud may protrude above the nut, locking the wheels. It must be trimmed with a grinder or hacksaw blade.

Well, the serving table is ready. The height of the tiers can be changed depending on the purpose and preferences.

You can make a table, the price of which will be much lower than the purchase, in a few hours. The simplicity of design allows you to not prepare drawings and neglect the accuracy of certain sizes. It will be convenient for beginners in the furniture business. You can make a design both for your needs and as a gift. Such a miniature mobile building is useful to every friendly hostess.

Share

Pin

Tweet

Send

Share

Send