To engage in active sports in the summer is not only pleasant, but also useful. And in winter you can work out at home. In this review we will tell you how to make a horizontal bar with folding bars from square and round pipes yourself.

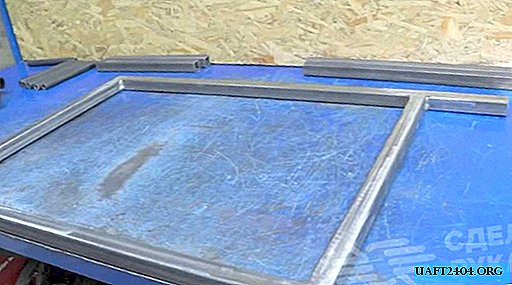

First, measure the size of the frame for your height. We weld using a square 4 tubes of suitable sizes. Next, we weld two tubes perpendicular to the edges.

In order to reduce pressure on the protruding tubes, we will build the jibs from the same pipe, but cut to 45 degrees.

We weld the structure and get a very powerful bed. In the lower part of the bed, we weld plates of sheet metal in the form of the letter P to emphasize the bars when unfolding.

The main stages of work

Now let's start making the horizontal bar itself. To do this, in the protruding part of the pipe, we select metal from opposite walls for the diameter of the pipe. We install the pipe in the resulting grooves, insert the pipe and weld it. If desired, you can give the pipe a slightly curved edge.

Next, we weld two pieces of pipes for a longitudinal narrow and wide grip. For pens on the bars we will use the same round pipe.

We weld to the edges vertically and horizontally along a piece of pipe. To keep the entire structure on the wall, we weld pieces of sheet metal along the inner corners of the bed.

We drill holes for the anchor of the required size. We clean all welds. Degrease the surface and primer the entire structure.

For greater convenience, you can make an emphasis on the back and armrests. To do this, you can use sheet wood (plywood, particleboard, OSB and others), foam rubber and leather.

We cut out the necessary dimensions of wood and foam, and we take a piece of leather with a margin for wrapping. We fix everything with a mounting stapler.

Add convenient handles to all tubes and our horizontal bar is ready. A detailed manufacturing process, see the video below.