With this home-made device at home, you can make various bent elements for metal gates, gates, doors and other forged products. It is very simple to make it - this does not require expensive materials, but only those that are easy to find in every workshop.

The main stages of work

As a basis for the manufacture of a mini-machine, a metal bar with two spiral curls at the ends will be required. The workpiece must be cut into two parts, and then welded together. Please note that you need to grab them only from the inside, and the outside should remain smooth.

If it’s not possible to grab it from the inside, then it is possible to make tacks on the outside of the snails, and then grind it well. As the base for the cochlea, a rectangular plate of 250x180 mm and a thickness of 4-5 mm can be used. After the “fitting”, we weld the snail in the center of the site.

Then, along the radius of the tail of the spiral in the plate, we drill two holes for the M8 bolts. From the cochlea, you need to cut off the tail and weld it to the bolts, so that it is convenient to start the workpiece. To install the platform on the desktop or workbench, it is additionally necessary to weld “paws” from the corners with holes for fastening to the plate.

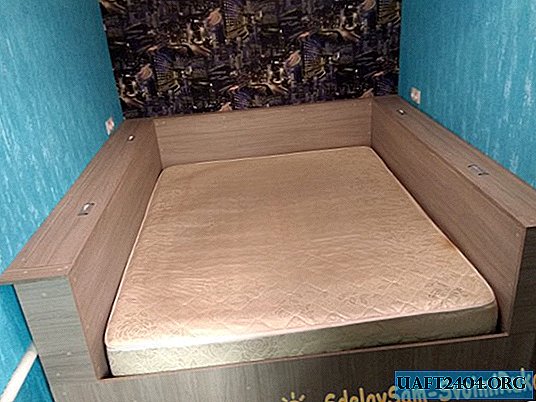

At the last stage of work, a guide sleeve is welded in the center of the cochlea, and a support is made from a piece of a profile pipe 20x20 mm and a handle from a steel strip with a small bend at the end at an angle of 90 degrees. Here is such a simple mini-machine for cold forging turned out in the end.